Meeting the Growing Demand for Biomass Processing

As the world transitions toward renewable energy, biomass energy has emerged as a key player in the quest for sustainable power generation. Biomass energy, derived from organic materials such as wood chips, agricultural residues, and even waste wood, is an efficient and renewable solution to reducing dependence on fossil fuels.

The rising demand for renewable energy, coupled with the need to meet stricter environmental regulations, has heightened the need for advanced machinery capable of processing large volumes of biomass efficiently. Acrowood’s equipment, designed specifically for high-capacity wood processing, provides biomass and renewable energy companies with the tools necessary to keep up with growing market demands while improving operational efficiency.

Biomass Energy Market Growth and Opportunities

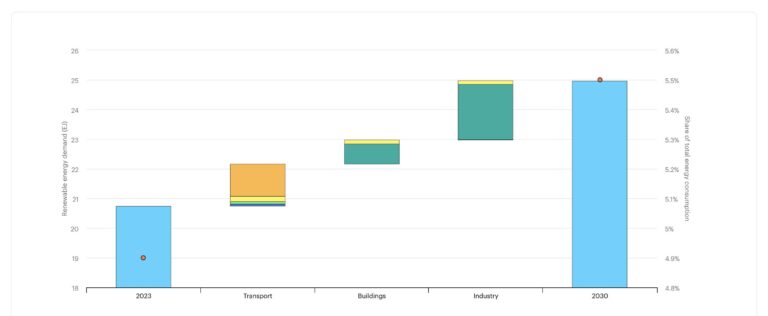

Biomass energy is rapidly gaining ground as a reliable, renewable source of energy. As governments and industries work to reduce carbon emissions and achieve their decarbonization goals, biomass has become a key contributor to this shift. The International Energy Agency (IEA) projects that global biomass energy production will continue to grow significantly, driven by the rising adoption of cleaner energy sources.

Screenshot

The surge in biomass energy demand necessitates an upgrade in processing technologies. To remain competitive and meet increasing biomass output, companies in the renewable energy sector must invest in machinery that streamlines their operations, reduces costs, and improves the quality of the feedstock used in energy production.

Biomass Market Growth Fuels Demand for Efficient Processing Equipment

As the demand for biomass increases, so does the need for equipment that can handle and process raw biomass materials. Acrowood’s chippers, grinders, and screens provide reliable and efficient solutions for biomass companies looking to streamline their material processing operations.

How Acrowood Machinery Supports Biomass Energy Production

Acrowood’s machinery is specifically designed to handle and process the various organic materials used in biomass energy production. Whether it’s wood chips for combustion, bark for biogas, or agricultural residues for biofuels, Acrowood’s products are engineered to provide high throughput, ensuring minimal downtime and maximum productivity.

Streamline Biomass Processing with Acrowood’s High-Performance Machinery

DiamondRoll Fine Screen is one of the cornerstones of Acrowood’s biomass processing solutions. By efficiently separating fine particles from larger wood chunks, this machine ensures that biomass feedstock meets the rigorous quality standards required for energy production. Not only does it optimize feedstock quality, but it also increases operational efficiency by minimizing waste and reducing the need for reprocessing.

Another key piece of equipment is the Air Density Separator, which uses airflows and density differences to separate lighter contaminants, such as dust, bark, and debris, from heavier biomass materials. This is critical in ensuring that the biomass is clean, consistent, and ready for conversion into bioenergy. The Air Density Separator helps reduce impurities that could affect the quality and efficiency of energy production, making it an indispensable tool for biomass companies aiming to maintain high standards and minimize the risk of inefficiencies.

The Dual-Drive Rotary Screen is another essential machine for biomass operations. This screen efficiently processes raw materials by sifting out contaminants, ensuring that only the most consistent, high-quality materials are used in bioenergy production. The ability to filter out unwanted material before it enters the energy conversion process improves both the efficiency and the output quality of biomass energy production.

Additionally, Acrowood’s Rechipper and Chip Cracker are designed to ensure that larger chunks of wood or biomass can be reduced to the appropriate size for bioenergy applications. The Rechipper reprocesses rough, oversized wood chips into smaller, more uniform sizes, optimizing them for energy production. The Chip Cracker, on the other hand, breaks down large pieces of biomass into smaller, more consistent chips, providing a steady flow of material for bioenergy conversion.

Maximize Biomass Processing Efficiency with Acrowood Machinery

Efficiency is at the core of Acrowood’s machinery, helping biomass companies increase throughput while maintaining the quality of their output. In the competitive biomass industry, companies must constantly look for ways to improve operational efficiency in order to stay ahead of growing market demand and regulatory pressure.

Enhance Biomass Processing with Acrowood’s Advanced Screening Solutions

The DiamondRoll Fine Screen not only improves the quality of the feedstock but also increases biomass processing efficiency by separating fine particles from coarse materials with minimal energy consumption. This allows for greater material throughput while ensuring that the biomass is of the highest quality for bioenergy conversion.

By investing in Acrowood’s robust machinery, biomass companies can achieve higher operational efficiency, reduced material waste, and improved profitability, all while meeting the growing demand for renewable energy. The Rechipper and Chip Cracker contribute to this efficiency by reducing raw biomass to a uniform size, ensuring consistent and high-quality feedstock that maximizes the energy yield from each unit of material.

Sustainability and Regulatory Pressures Driving Adoption

With increasing governmental regulations focused on sustainability and carbon neutrality, biomass energy is rapidly becoming an essential part of the solution to global environmental challenges. Biomass provides a renewable energy alternative that reduces the reliance on fossil fuels and lowers carbon emissions. The shift to biomass energy also aligns with the broader push for cleaner, more sustainable energy production methods.

Comply with Environmental Regulations Using Acrowood Equipment

Acrowood’s equipment not only enables companies to process biomass efficiently but also helps them meet the strict environmental regulations set by governments worldwide. By reducing waste, optimizing feedstock, and improving the quality of the materials used in energy production, Acrowood’s machinery plays a pivotal role in helping biomass companies stay compliant with industry-specific regulations.

For instance, Acrowood’s Air Density Separator ensures that contaminants are effectively removed, reducing material waste and minimizing emissions during the biomass processing stage. This is crucial for companies seeking to comply with emissions regulations and for those aiming to operate in environmentally responsible ways.

Future-Proof Your Biomass Production with Acrowood

The renewable energy sector is expected to continue growing, driven by both consumer demand for cleaner energy and governmental efforts to meet carbon-reduction targets. As this trend continues, biomass energy will become increasingly important. Acrowood’s advanced machinery offers biomass companies the tools they need to process large volumes of organic materials efficiently, meet market demand, and adhere to environmental standards.

Invest in Acrowood’s Solutions to Future-Proof Your Biomass Operations

Acrowood’s machinery is designed with scalability in mind, allowing biomass companies to expand their operations as market demand increases. With solutions like the DiamondRoll Fine Screen, Dual-Drive Rotary Screen, Rechipper, Chip Cracker, and Air Density Separator, biomass producers can ensure that their operations are equipped to handle increased volumes of feedstock without compromising on efficiency or quality. These machines also provide the flexibility needed to adapt to evolving market and regulatory changes, ensuring that companies remain competitive for years to come.

Strengthen Your Biomass Production with Acrowood

As the global demand for renewable energy continues to grow, biomass energy will play an increasingly critical role in global energy solutions. Biomass companies need high-performance, reliable machinery to process the raw materials used in energy production efficiently and in compliance with environmental regulations. Acrowood’s machinery, including the DiamondRoll Fine Screen, Dual-Drive Rotary Screen, Air Density Separator, Rechipper, and Chip Cracker, provides the tools that biomass producers need to meet both market and regulatory demands.

By investing in Acrowood equipment, biomass companies can enhance operational efficiency, improve the quality of their feedstock, reduce waste, and ensure that they remain competitive in the growing renewable energy market. With Acrowood, companies can position themselves as leaders in the biomass energy sector and future-proof their operations for years to come.