SCREENING

HD Disc Scalping Screen

Effectively remove gross oversized pieces

Acrowood Disc Scalping Screen

The Acrowood Disc Scalper Screen eliminates material handling problems and downstream damage to equipment. Disc Scalping screens are high capacity shaft-based machines with spacers separating individual discs down the length of the shaft. The intent is to let the majority of chips pass quickly between discs and over the round surface of the spacers.

Disc Scalping Screen Features

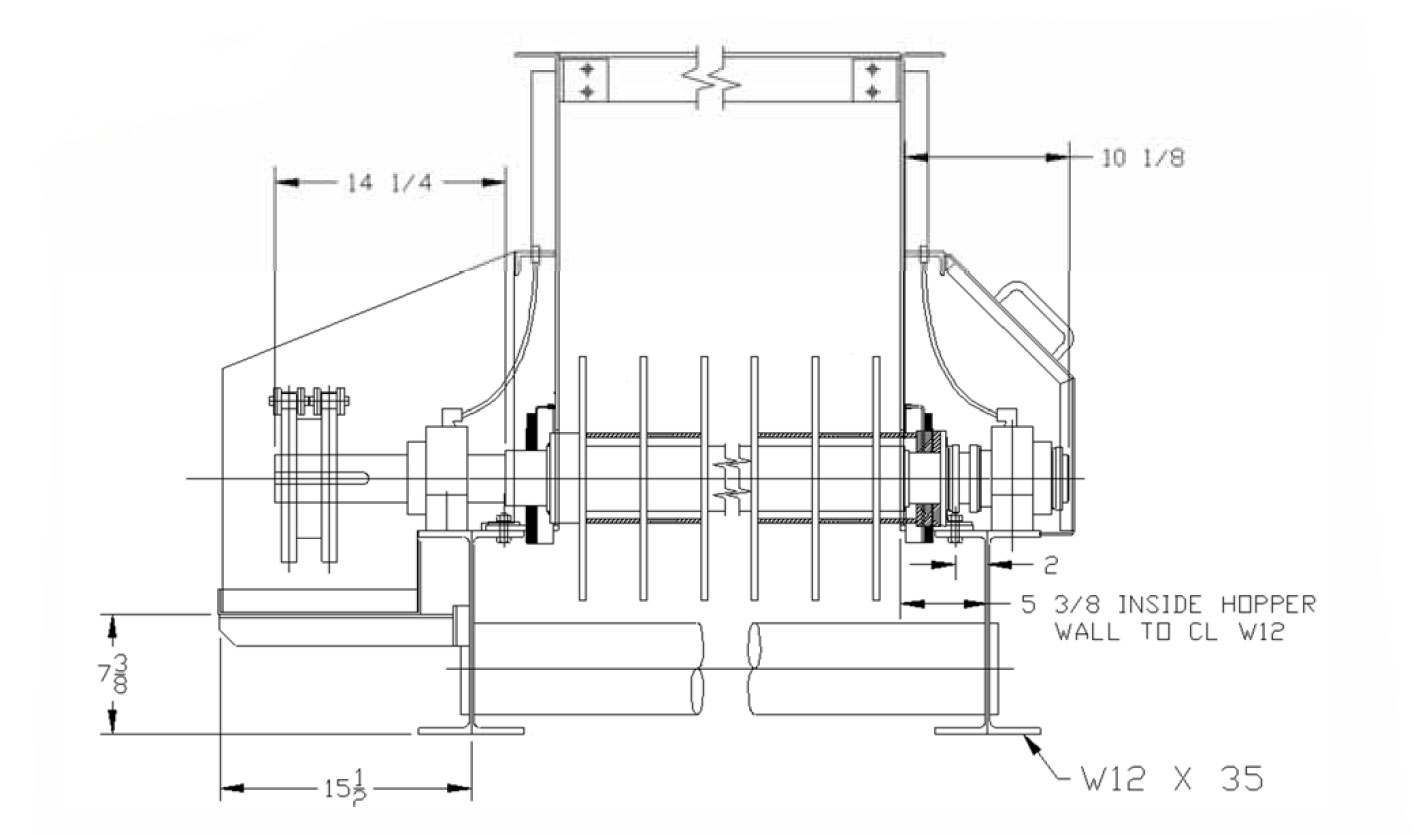

- Robust and super heavy-duty I-beam construction

- Wide-flange beam sub-base with pillow block bearings located outboard from hopper walls and potential contamination

- Easy maintenance with segmented, removable hopper walls for excellent shaft access

- Spacer-disc shaft assemblies with heavy-duty discs and spacers. Options for different metallurgy and thicknesses

- Lubrication-free and trouble-free drive system with oversized, sintered bushing chain drive

- Dust containment a result of shafts sealed at hopper walls and optional screen covers

- Proven performance

Disc Scalpers

The Acrowood Disc Scalper is designed to remove gross oversize pieces which could cause material handling problems in or damage to downstream equipment.

- Scalper base of wide flange I-beam with 4” steel pipe for cross ties.

- Segmented hopper walls for simple shaft changes.

- Shaft assemblies with discs and spacers slipped over square tubing, held in place using a special compression system.

- Spherical roller pillow block bearings mounted outboard of the hopper walls, away from potential contamination.

- Standard discs are AR plate, 15” diameter and 3/8” thick

- Disc tooth profile and spacing are selected to optimize selectivity

Shafts are assembled using pipe spacers and heavy AR plate discs on a mechanical tubing central core. Spacing is adjusted to suit specific applications. Different metallurgies and disc thicknesses are available.

Excellence In Chip Processing

Sprockets with hardened teeth are fixed to the shafts using tapered bushings. Pillow block bearings are located outboard of the hopper walls, away from potential fines contamination. The use of sintered bushing chain completes this reliable drive system and requires no periodic lubrication or oil bath.

Scalping screens typically have an interfacial opening (IFO) of between 0.5 and 6 inches. The overs intended to be rejected are typically larger than the IFO by 0.25 to 1” and are related to the spacing chosen for the application.

- Fully enclosed drive

- Bearings easily accessed from either side of the screen.

- The lube-free drive uses heavy RSD 140 sintered bushing chain.

- Outboard mounted pillow block bearings removed from dust contamination.

- Shaft seals contain fugitive dust from the hopper walls.

Disc Scalper Screen Machine Diagram

Robust design | Trouble-free operation | Belt or lube-free chain drive

Acrowood Disc Scalping Screen Engineering Diagram

Applications

-

Chip Plants

-

OSB Plants

-

Pellet Plants

-

Pulp Mills

-

Sawmills

-

Shavings Mills

Outboard mounted pillow block bearings removed from dust contamination.

Shaft seals contain fugitive dust from the hopper walls.

The HD Disc Scalping Screen brochure

Request the disc scalping screen brochure in PDF format for easy reading.

Case Study: Primary Thickness Screening, Efficiency and Chip Size Distribution

Scalping Screens are high capacity, shaft-based machines with spacers separating individual discs down the length of the shaft. The intent is to let the majority of chips pass quickly between the discs, sliding between discs and over the round surface of the spacers.

Case Study: Pulping System Sensitivity to Chip Quality

Fines and grit must be removed, and overs must be processed into Accepts. The pin chips, if screened out, can be sent to the batch digesters in the same mill allowing the continuous digester to operate at a maximum rate.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.