DISTRIBUTION & SEPARATION

Screw Distributor

Precise, consistent material flow to chip & sawdust screens

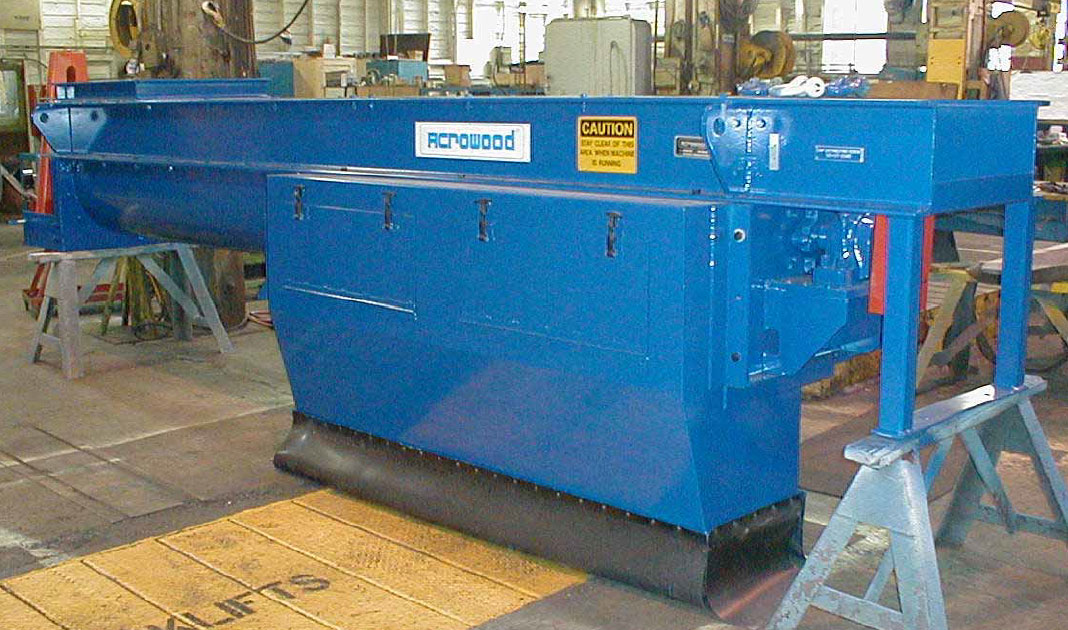

Acrowood Screw Distributor

The Screw Distributor provides a highly efficient solution for metering the flow of materials to chip and sawdust screens. The Screw Distributor is a popular component from Acrowood’s line of distribution and separation machinery or mills looking to optimize material flow.

Screw Distributor Features

- Even distribution of material

- Low maintenance

- Heavy-duty construction

- Center Fed or Side Fed configuration

- Trouble free operation

- Option for either shaft mounted or foot mounted gear reducers

Typical Applications

- Chip Plants

- OSB Plants

- Pellet Plants

- Pulp Mills

- Sawmills

- Shavings Mills

View of a Side-fed Screw Distributor mounted over an Acrowood DiamondRoll screen.

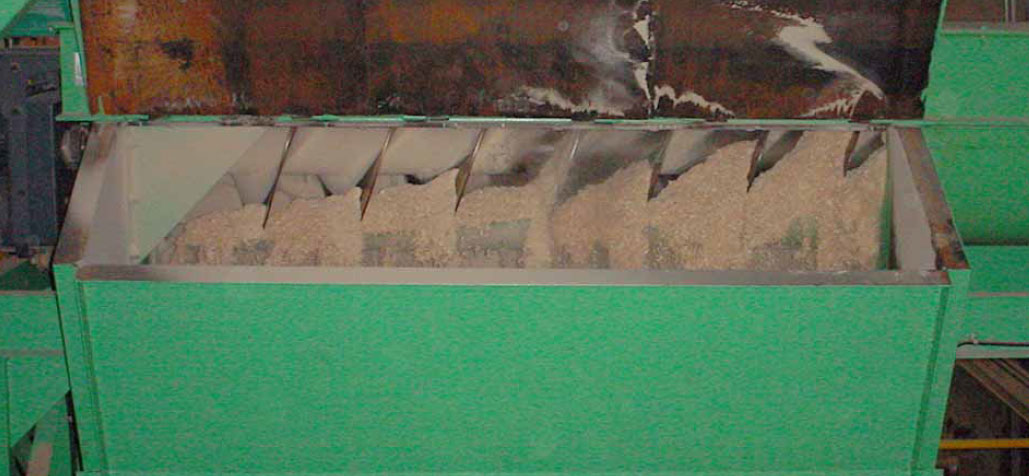

View of a Side-fed Screw Distributor with open gates, discharging saw dust onto a DiamondRoll screen mounted directly below.

Screw Distributor – Detail of distributor with open discharge enclosure and discharge gates.

The Screw Distributor eliminates the problem of uneven metered wood chip flow to your screens for any application.

Side Fed Screw Distributor – front view of distributor with optional discharge enclosure.

Side Fed Screw Distributor Details – open enclosure with discharge gates.

Side Fed Screw Details – focused detail of adjustable discharge gate.

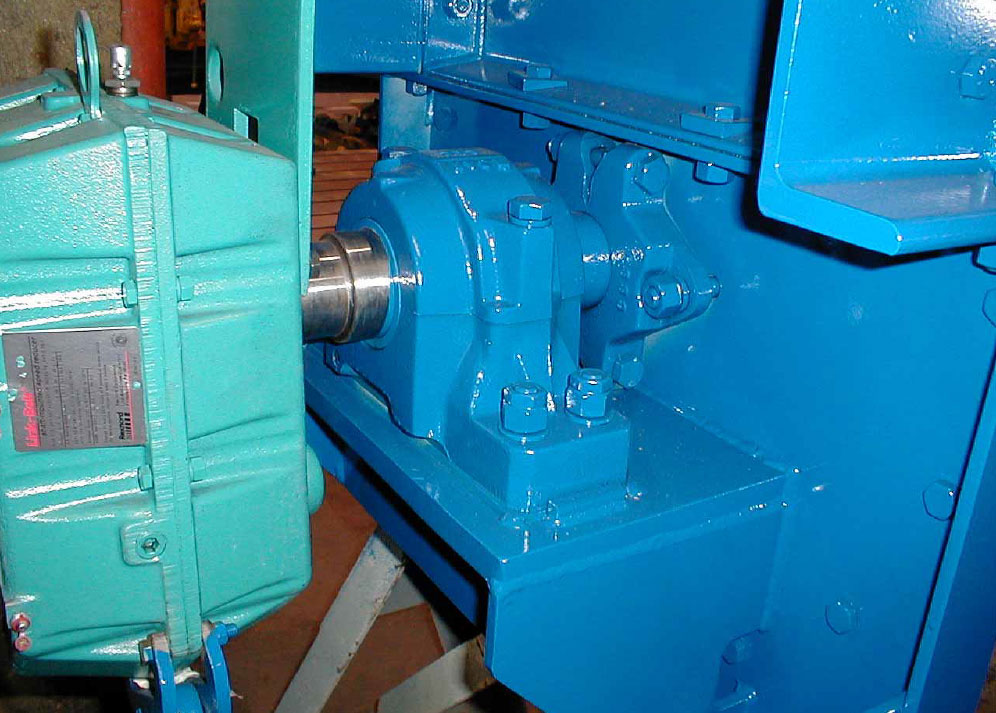

Side Fed Screw Distributor Details – shaft mounted reducer with pillow block bearing and gland seal.

Side Fed Screw in Operation – side fed screw discharging sawdust onto a DiamondRoll screen.

Side Fed Screw Distributor Details – shaft mounted reducer with pillow block bearing and gland seal.

Side Fed Screw in Operation – side fed screw discharging Southern Pine wood chips onto a DiamondRoll screen.

Center Fed Screw Distributor

Center Fed Screw Details – Screw inlet with opposite flights.

Center Fed Screw Details – adjustable discharge gates.

Center Fed Screw Details – idler bearing with gland seal and speed switch enclosure.

Center Fed Screw – distributing wood chips below to a DiamondRoll Screen.

The Screw Distributor brochure

Request the Screw Distributor machine brochure provided to you in PDF format for easy reading and printing.

Case Study: Pulping System Sensitivity to Chip Quality

In many cases this problem is solved through the action of the plug feed screw that feeds the chips into the refiner. This high compression, high shear screw smashes the large chips before they get to the refiner, and the environment inside the screw casing is hot and steamy, softening the center of the largest chips adequately.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.