DISTRIBUTION & SEPARATION

Air Density Separator

Maximum control for superior contaminant removal

Acrowood Air Density Separator

Get superior contaminant removal with reduced loss of acceptable fiber. Small contaminants are efficiently removed, including, including non-ferrous metals, plastics, and other contaminants, by using the Acrowood Air Density Separator (ADS).

Air Density Separator Features

- Effective removal of high density contaminants from a variety of woody or biomass materials

- Excellent control over contaminant removal with adjustable air velocity and separation zone depth

- Control system automatically compensates for changing flow rates and operating conditions

- Years of operating experience in a variety of applications including pulp and paper woodyards, particleboard, urban wood waste, as well as other applications

- Low fiber losses

Air Density Separator - Sizing

| Model | wdt_ID | Separation Zone Width (ft) | Fan Power (HP) |

|---|---|---|---|

| 2914 | 1 | 2.4 | 60 |

| 4818 | 3 | 4 | 100 |

| 6020 | 4 | 5 | 125 |

| 7222 | 5 | 6 | 150 |

| 8624 | 6 | 7 | 200 |

Precise Air Flow

Ideal for overthick slicing operations

Exact air flow control for superior separation efficiency allows the Acrowood Air Density Separator to easily remove knots and other contaminants.

One of the biggest dangers to pulp mill equipment is contamination from bits of wire and stones, nuts, bolts, and knots. Even pieces of brass, copper and nails can cause severe damage.

Removal By Air

An Acrowood Air Density Separator easily removes:

- Knots

- Stones

- Rocks

- Ice lumps

- Blacktop or pavement

- Bricks

- Metal

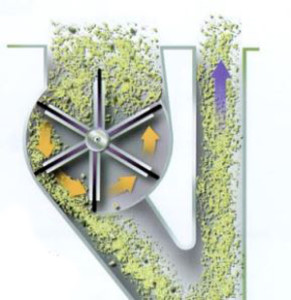

The Basic Principle

ADS systems operate on the basic principle that the density or weight of a contaminant is greater than the good oversize chips processed. But what makes a superior machine, an Acrowood machine, is the ability to create and control precise air movement in a larger separation area.

Reports Worldwide

In installations worldwide, reports are the same: The Acrowood ADS system provides maximum control for superior contaminant removal with minimum loss of good fiber.

Precise Control

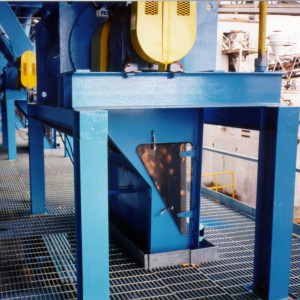

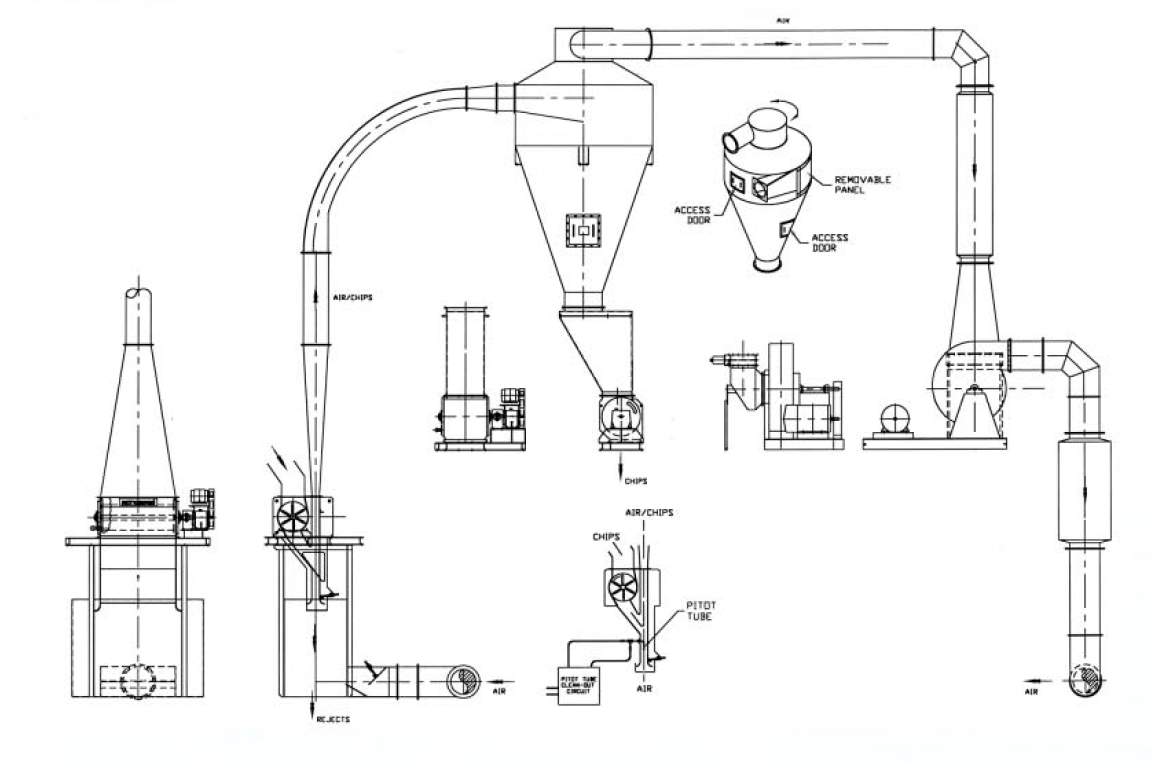

The ADS includes an infeed rotary airlock; a tapered, ported separation chamber; transfer piping to and from the cyclone; a heavy duty cyclone; a high-performance industrial fan with a metal fabricated base; and the necessary electronic and air low control hardware.

The separation zone design is critical to provide maximum capacity and precision set-up for the feed materials.

Maximum Selectivity

An adjustable back panel allows the large separation chamber to be preset for the most efficient operation. Maximum selectivity is achieved when the air flow permits uniform mixing of air and chips across the entire width of the chamber.

A rubber tipped rotary airlock feeds chips into the separation chamber, minimizing air leakage and preventing air backwash. Air turbulence is minimized by the chamber’s shape.

Effectively Remove Small Light Contaminants

The Acrowood Air Density Separator is ideal for a variety of industries, from the board industry to wastewood processing.

Incoming raw material can be effectively cleaned for particleboard and medium density fiberboard, removing contaminants that can cause costly damage to machinery and create waste in the end product.

Ideal Industry Uses

The ADS configured for these industries is ideal for separation of:

- Sawdust

- Urban wood waste

- Hogged wood

- Shavings

- Chips

Materials effectively cleaned with an ADS won’t cause damage to the plates used in MDF processes, and can be sent directly to refiners.

Ready For Processing

Urban wood and wastewood materials can also be cleaned to remove rocks, nonferrous metals, plastics and fasteners, and large sand and grit.

The ADS has proven to be so effective that wood cleaned with an Acrowood ADS can be directly processed for production.

Separator Air Flow

Small sand and grit are light enough to be retained with the good fiber. Nuts, bolts, and broken rocks as small as the size of a match head (2-3 mm) will fall out consistently.

Since materials processed for these industries is typically very light, the separator can be configured for a lower air velocity that efficiently removes these smaller contaminants.

Engineered Model Diagram Drawing - of the Air Density Separator

The Air Density Separator brochure

Request the air density separator machine brochure provided to you in PDF format for easy reading and printing.

Case Study: Pulping System Sensitivity to Chip Quality

Overall the only really objectionable “chips” are the knots present in the infeed flow. These are removed through the use of an Air Density Separator (ADS). Knots are the embedded branches that break out of the stem during chipping making large, resin-soaked, curly-grained dense wood chunks that do not grind into pulp but produce shives and “stickies”.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.