SCREENING

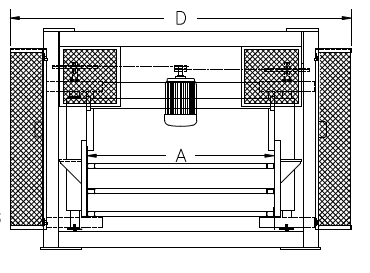

Dual Drive Suspended Rotary Screen

Designed for long life & efficient screening.

Acrowood Dual Drive Suspended Rotary Screen

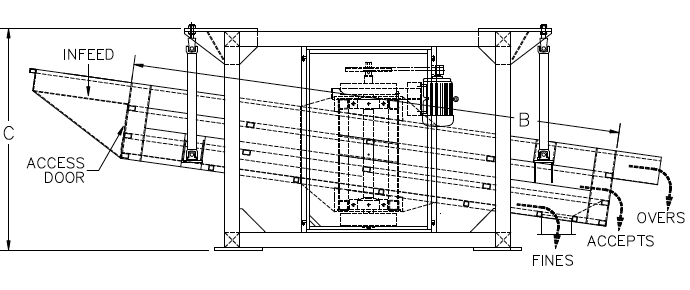

Acrowood’s Dual Drive Suspended Rotary Screens are unique in the market employing the use of dual drives with no center drive box or drive tube, leaving the entire upper and lower screening deck surfaces clear for high capacity screening. Easy maintenance and a superior design set this screen apart.

Dual Drive Suspended Rotary Screen Features

- Versatile design allows screen suspension from building structure or a support frame

- Reliable, heavy-duty universal joints and rigid shafts reliably suspend screens

- Outboard mounted drive shafts allow for easy maintenance access

- Balanced drives result in minimal dynamic loading to the building structure

- Screen decks are unobstructed by drive components yielding higher capacity

- Screen discharges can be custom designed to best suit installation requirements

- Sealed full width and depth access door provides excellent access for inspection, deck cleaning and screen plate changing

Spouts

Each Acrowood Rotary Screen has several standard spout configurations to choose from. Acrowood can also customize spout configurations to suit nearly any application.

Applications

- Chip Plants

- OSB Plants

- Pellet Plants

- Pulp Mills

- Sawmills

- Shavings Mills

Acrowood Dual Drive Design

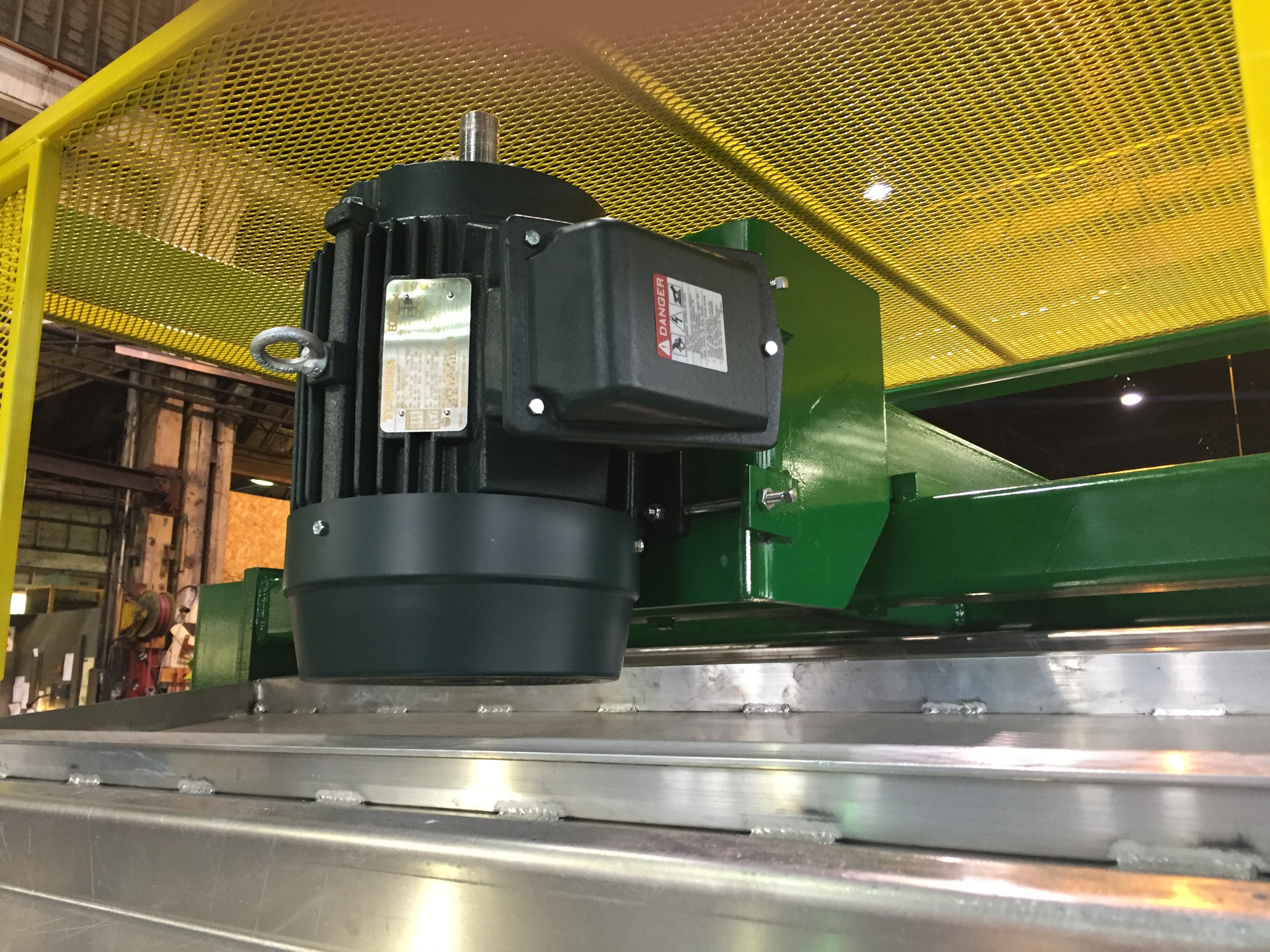

With Acrowood’s Dual Drive design, all drive components are located outside of the screen pan for easy access, inspection and maintenance. The two identical outside drive assemblies transmit forces to the pan at the strongest part of the assembly. The drive support areas are fabricated separately with continuous welds and are thermally stress relieved. SKF Spherical Double Row bearings, with a B-10 Life in excess of 100,000 hours, offer years of trouble free service.

Dual Drive Suspended Screen

The counterweight drive shafts are powered and synchronized by a pair of Gates Poly chain drive belts from a single motor. A counterweight alignment bar permits drive belt installation by a single person.

While most installations use a top mount motor, a bottom mounted motor configuration is available as an option and may be preferred for outdoor installations. Acrowood’s combination of speed and amplitude yield optimum material movement and particle separation.

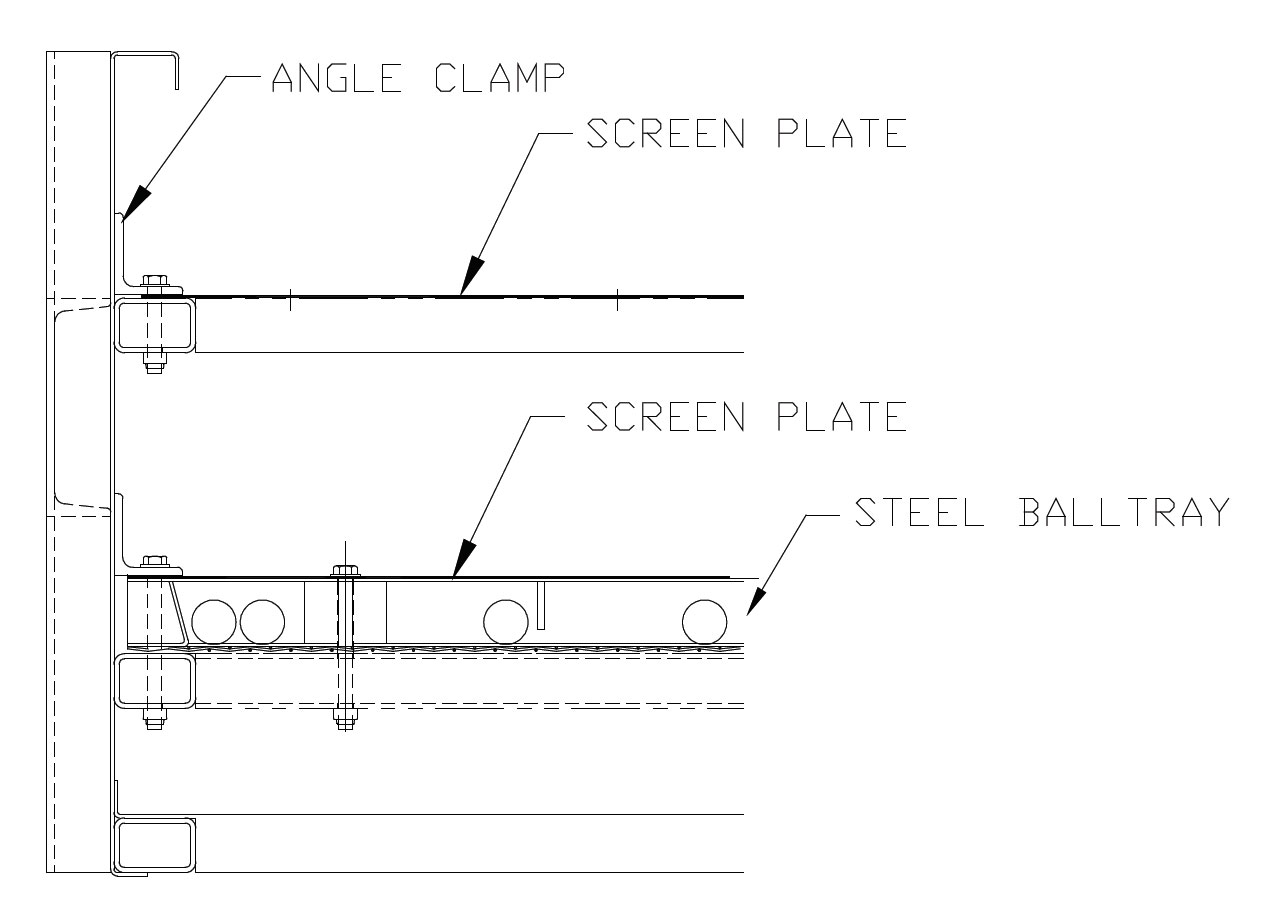

Ball Deck Option

Screen plates are supplied in manageable, uniform sizes and held in place by angle and flat hold down plates with Stainless Steel fasteners.

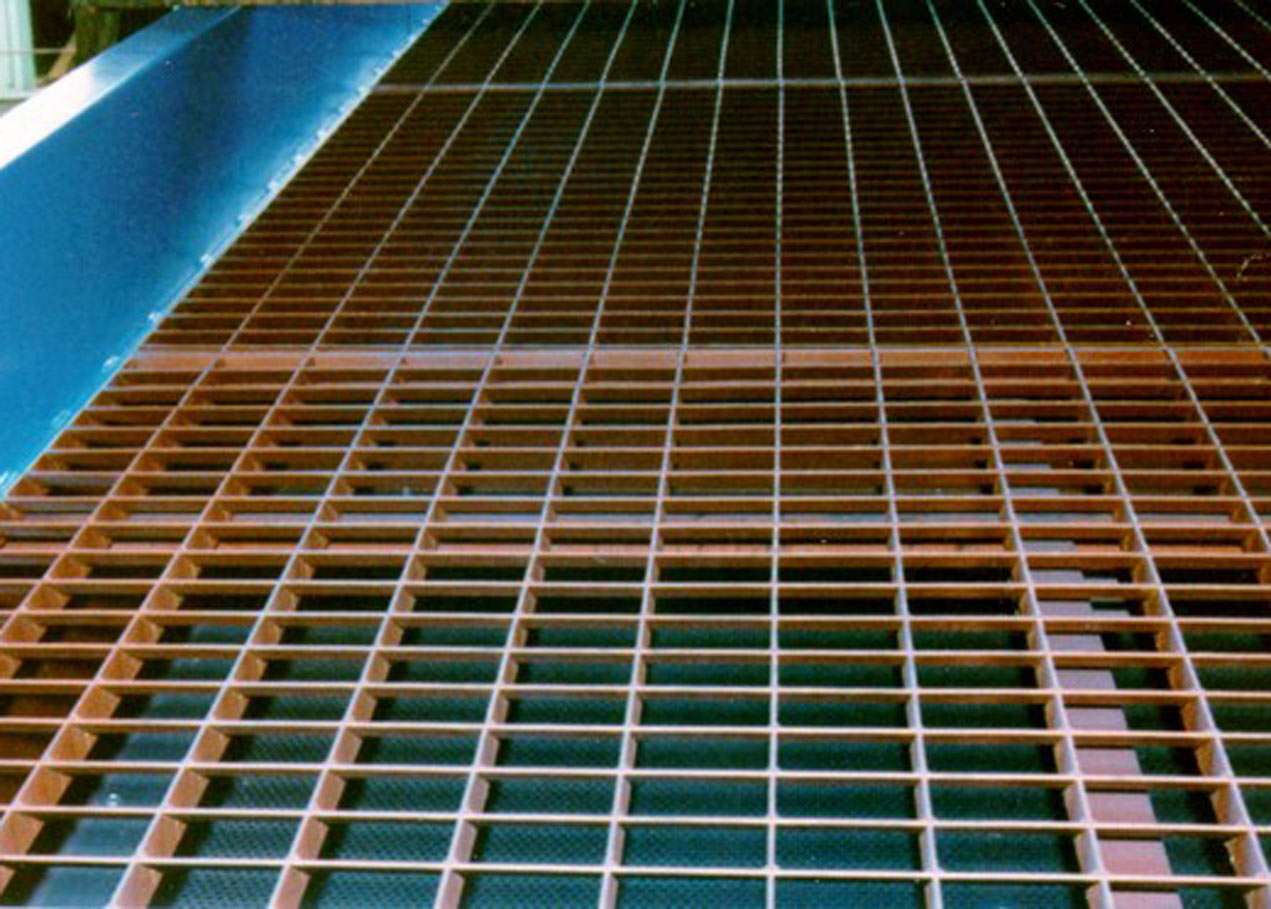

Louvered Deck Option

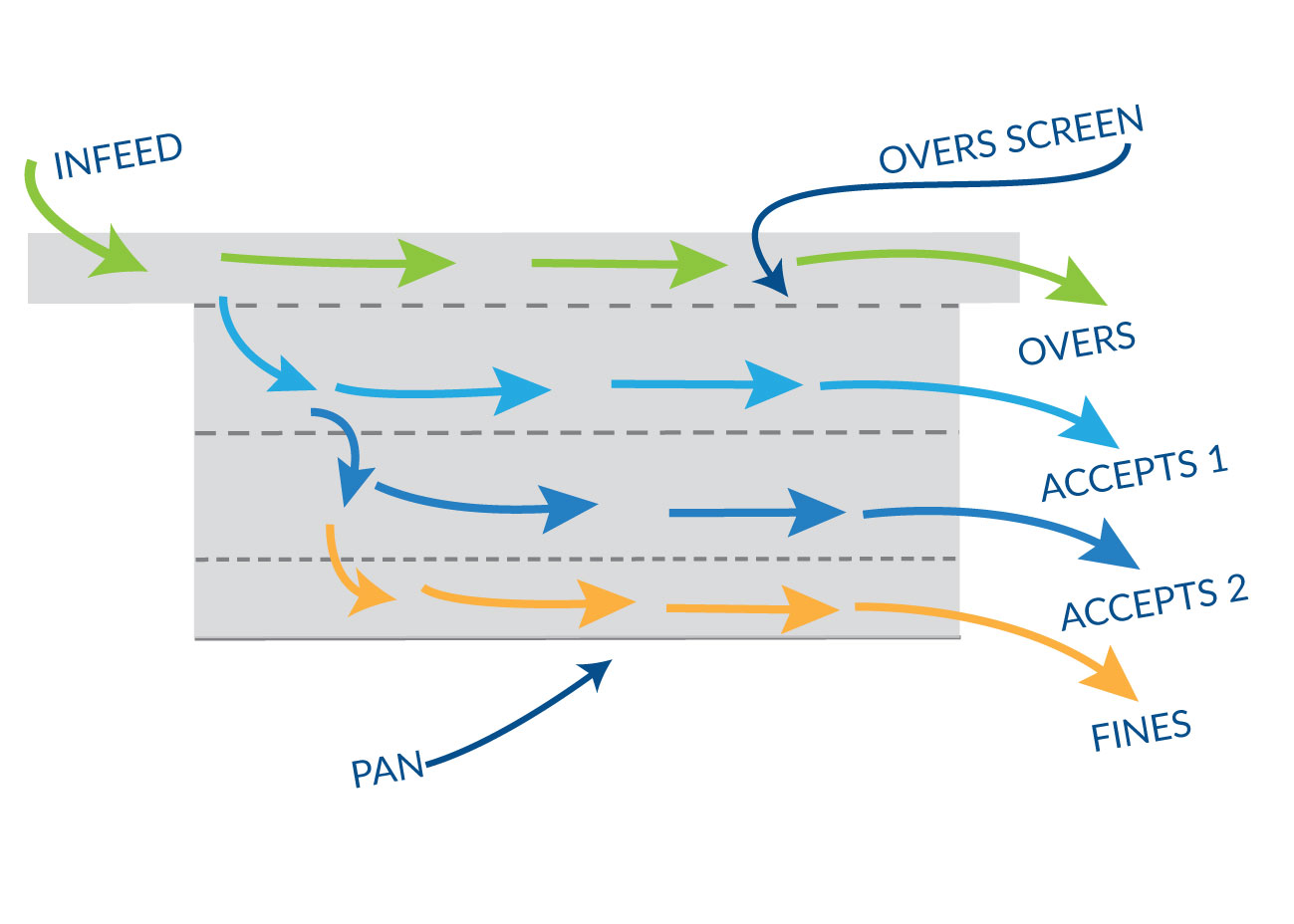

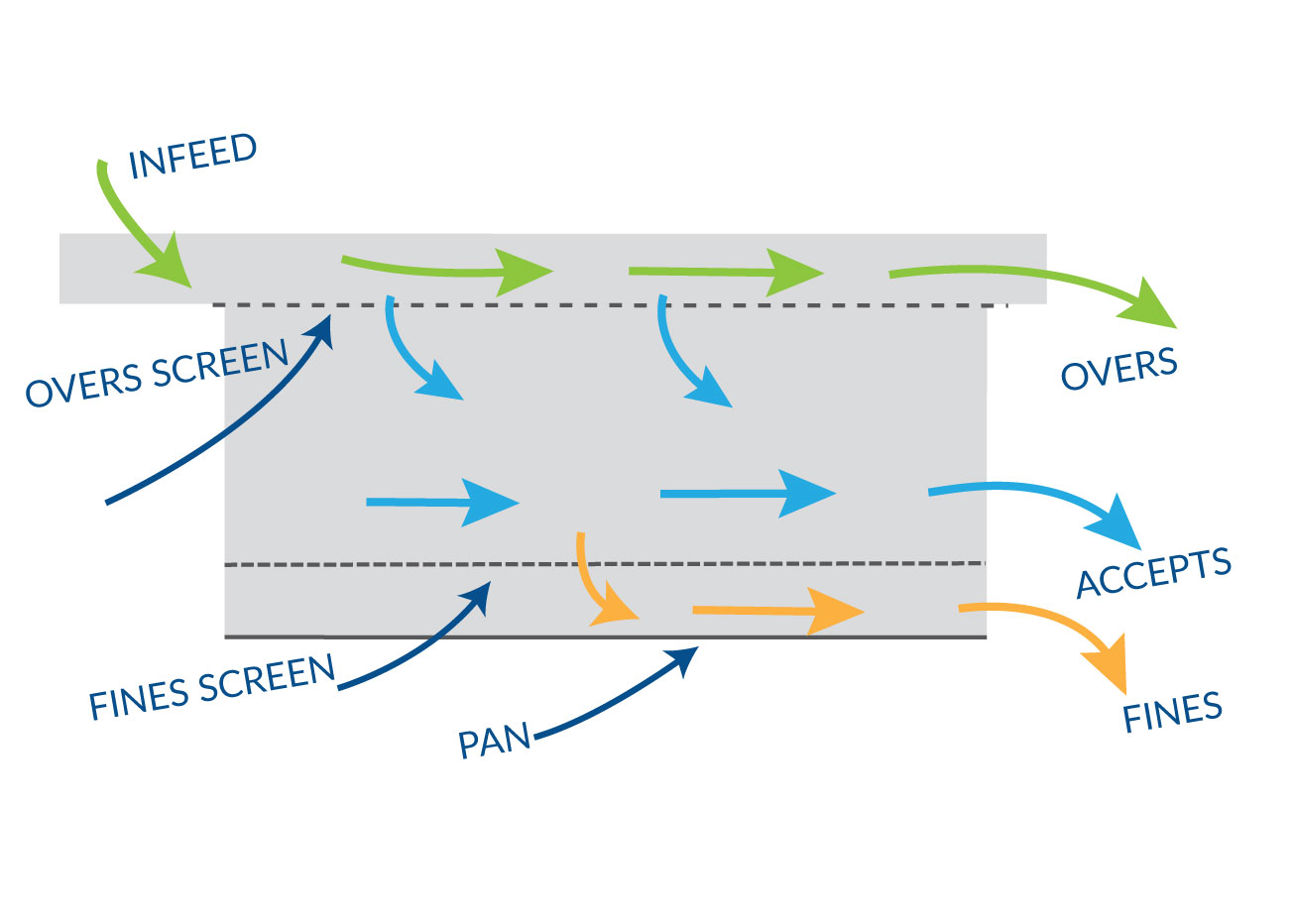

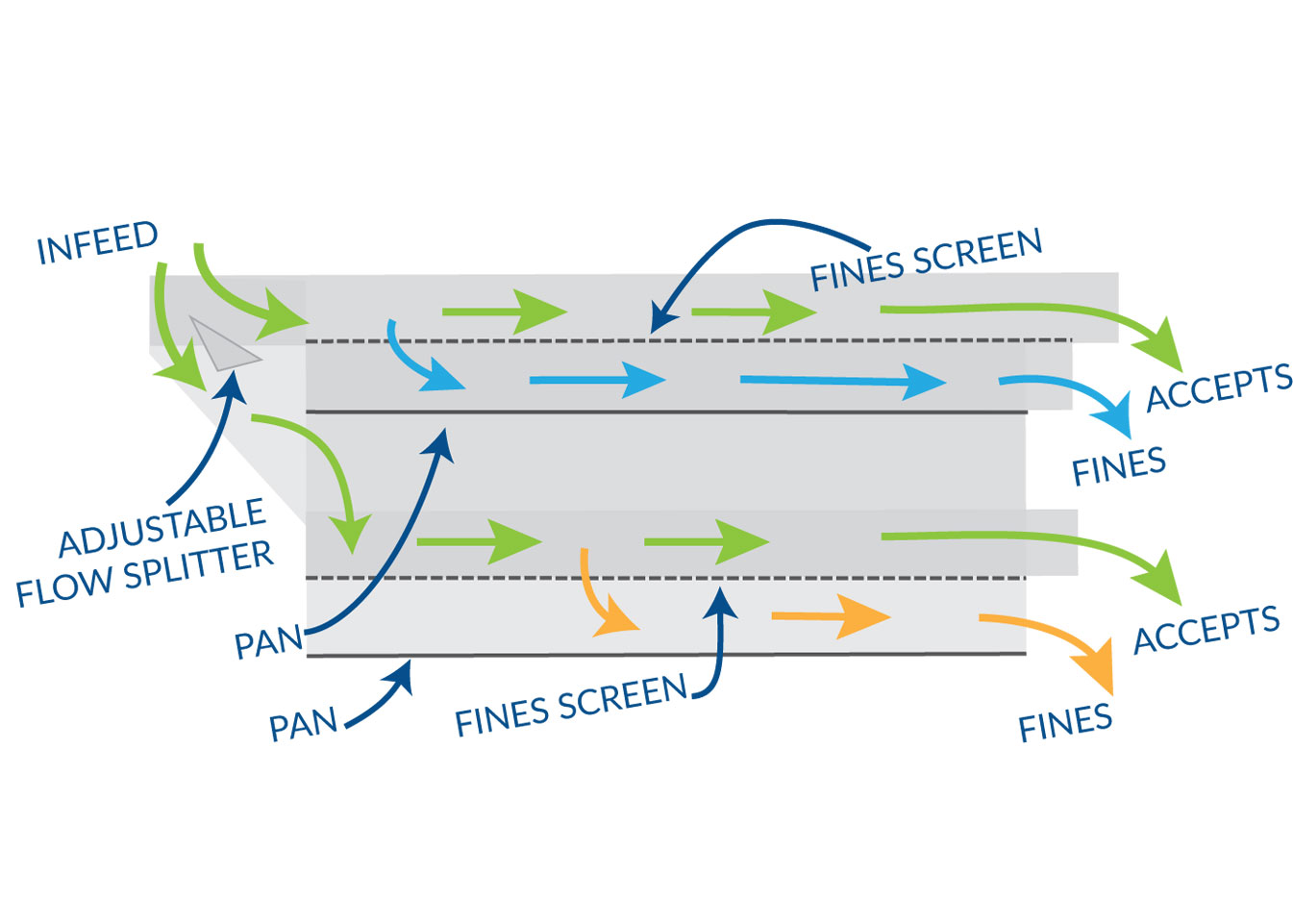

Capacities and dimensions based on standard two deck, three sort screens. Dimensions are approximate. Use only Acrowood certified drawings for installation. Screen capacity will vary with infeed chip quality and desired separation points. Discharge chute dimensions are for standard, full-width accepts and overs discharge.

Multiple Screen Styles Available

In addition to offering 2-Deck and 3-Deck screens, Acrowood offers Double-Single screens for single-sort applications providing twice the capacity in the same footprint.

3-Deck Screen

2-Deck Screen

Double-Single Screen

Maximum fines removal

Acrowood Dual Drive Suspended Rotary Screen combined with DiamondRoll® Fines Screen for maximum fines removal.

Over 600 Large Dual Drive Suspended Rotary Screens have been sold.

Heavy Duty Universal Joints & Rods

Rigid, large diameter universal joint assemblies and rods support the Dual Drive screen from either building structure or a provided support frame, built to last providing years of trouble free service, and are easy to adjust and change. These assemblies also limit the amount of dynamic loading transmitted to building structure.

On Site at Acrowood Development Center

The Dual Drive Suspended Rotary Screen presented in this video is located on site at the Acrowood Development Center in Everett Washington.

This video illustrates the smooth rapid motion of the suspended screen; leveraging the dual drive design, view the rotary screening machine operating from a variety of angles and inspect the high quality engineering that makes Acrowood the industry leader in wood chip screening technology.

Custom Chip Screening Solutions

The Acrowood support frame includes and supports necessary drive guarding. Bolted assembly support frames are available as an option.

Suspended Rotary Screen

Twin, outboard mounted drives keep screen decks clear from obstruction and allow simple maintenance access to bearings and counterweights.

Custom Discharge Screens

Screen discharges can be custom designed to best suit installation requirements.

Full Access Door

A sealed full width and depth access door at the infeed of the screen provides excellent access for inspection, deck cleaning and screen plate changing. (Along with smaller fines pan clean-out ports.)

The Dual Drive Suspended Rotary Screen brochure

Request a dual drive suspended rotary screen brochure provided to you in PDF format for easy reading and printing.

Case Study: Fines Screening with Rotary and Roll Screens

To achieve fluidity it is necessary for the Rotary Screen to have a certain velocity of rotation and frequency. Traditional screens had a typical operating RPM of 180. At this rate it was possible for the material to move sluggishly down the screen plate, preventing this fluid condition. Current screens operate at between 235 and 300 RPM. This higher frequency, coupled with modifications in amplitude of motion, create the necessary fluid condition.

Case Study: Pulping System Sensitivity to Chip Quality

In most sulfite mills a chip length of 15 to 18mm is used, and a rotary screening system is used to insure that over length and oversize chips are rechipped.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.