SCREENING

Raised Roll Disc Thickness Screen

Selective separation of overthick chips

The Acrowood Disc Thickness Screen

To meet the performance challenge of rejecting overthick chips without also rejecting acceptable chips, Acrowood developed the Raised Roll Disc Thickness Screen. This configuration provides effective chip mat agitation, achieving both high overthick removal and low accepts carry-over.

Disc Thickness Screen Features

- Excellent chip agitation provides quick passage of fines and small chips

- Effective overthick removal efficiency with high throughput in a relatively small footprint

- Heavy-duty design uses wide-flange beam sub-base

- Bearings protected from contaminants with placement of pillow-block bearings mounted outboard of screen hopper walls

- Discs are welded to shafts via highly accurate computer-controlled welding method for excellent screen accuracy and high strength shaft construction

- Minimal maintenance a result of robust, sintered bushing chain drive with hardened sprockets. No sealed oil bath or periodic lubrication required!

Raised Roll Disc Thickness Screen

Raised Rolls means more selective overthick chip screening.

Highly selective thickness screening is achieved by efficiently rejecting the overthick chips without also rejecting acceptable chips.

To meet this performance challenge Acrowood has developed a new disc screen: The Raised Roll, its configuration provides effective chip mat agitation, achieving both high overthick removal and low accepts carry-over, resulting in maximized chip yield, chip quality and chip uniformity. Helping to maximize efficiency, quality and cost effectiveness of your entire pulping process.

Up to 97% Overthick Chip Removal. Up to 18% Accepts Carry-Over

Raised Toll Disc Screens process chips differently than any other thickness screening method, and that’s why they do more complete and selective job of chip thickness separation.

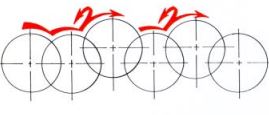

On the Raised Roll Screen, chips travel across alternately elevated shafts in a sinusoidal path. This non-linear path “breaks” the chip mat, increases chip agitation and dwell time, while its spreads the chip feed evenly along the full shaft length. All these factors enhance screening performance.

In addition to the selective separation of overthick chips, the Raised Roll Disc Thickness rapidly segregates and concentrates pin chip and fines, reducing the amount of screening area required for secondary processing.

Longer Life Less Maintenance

Since the Raised Roll configuration spreads chips evenly along the full shaft length, wear is also distributed evenly. So discs have long wear life, and because the chips travel in the rotational direction of the shafts, disc damage is minimized.

The welded shaft assembly utilizes 1/4 inch thick discs which have hard chromed plated teeth This configuration provides long wear life and excellent IFO accuracy. A variety of shaft assembly designs and disc metallurgies are available to meet each application requirements.

Better Screening Performance You Should See For Yourself

The Raised Roll Primary Disc Screen has become the first choice of mills who technically compare long-term operating performance and durability. It’s currently being used in systems running at up to 140 units per hour in a single line.

One of the best ways to judge the Raised Rolls Screen performance is to see it in action for yourself – screening your chips-in the Acrowood Development Center. All it takes to make arrangements is to call Acrowood.

No matter what type of chips you process, no matter what capacity you want to run, we can engineer a system to meet your needs.

The Disc Thickness Screen brochure

Request the Raised Roll Disc Thickness Screen brochure in PDF format for easy reading.

Case Study: Chip Thickness Screening and Chip Quality in the Pulp Mill

Fines, Pins, Accepts and Overthick chips. Disc Thickness Screens are essential when it comes to sorting and screening chips for achieving maximum acceptable chip thickness.

Case Study: Primary Thickness Screening, Efficiency and Chip Size Distribution

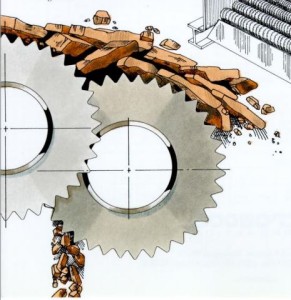

Disc Thickness Screens were adapted from Scalping Screens. The discs are used to provide a motive force for the chunks and overs that need to be removed. Lobes or star-shaped discs have been used depending on the material. Lobes were generally used in bark or fuel applications and star-shaped discs were used in applications involving chips.

Case Study: Pulping System Sensitivity to Chip Quality

The use of a rotary screen or simple thickness screen will isolate these large knots and the larger chips into a flow that can then pass through the ADS where the knots are removed. Small knots less than 6-8 mm thick do not seem to cause much trouble, but the large knots do.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.

The Disc Thickness Screen is only one component in Acrowood’s complete line of chip processing equipment.

Request a download of our complete wood chip processing product line brochure