Acrowood provides the highest quality chip screens for mills around the globe

Acrowood screens are specifically engineered for solving woodyard challenges and maximizing the highest yields of usable chips for your application.

Rotary Screens, Roll Screens, Scalping Screens and More

Whether you need excellent flake agitation and separation for your OSB application, effective quick overthick removal and chip thickness screening, or a disc scalping screen for gross removal of over sized pieces that cause material handling problem to downstream processing equipment. We also have an advanced shaker screen (Rotary screen) that combines two screening functions in a single screen for forest products applications.

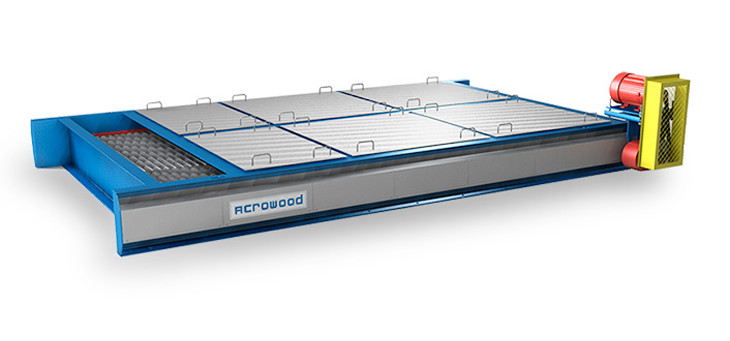

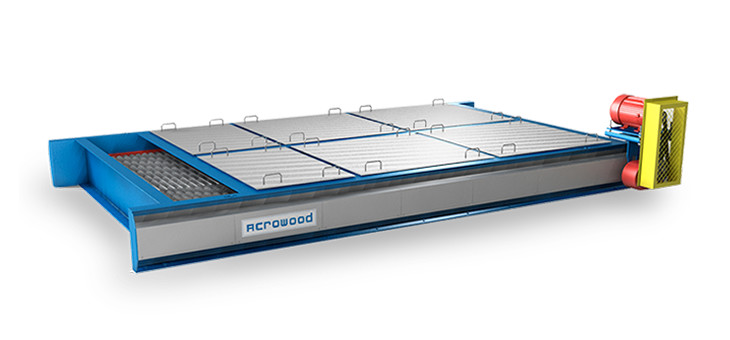

Trillium OSB Strand Screen

The Acrowood Trillium Screen is superior at screening of dry or green OSB strands, reducing downstream processing costs. The triangular shaped dsics allow for extra agitation and is build on same drive design as the DiamondRoll.

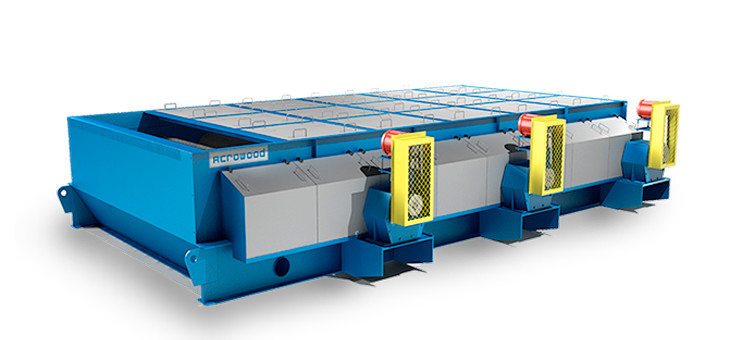

Disc Thickness Screen

Acrowood’s Disc Thickness Screens share the same traits as other Acrowood screens: low maintenance, easily sealed for dust containment, heavy-duty construction, and outstanding screening capacity, chip agitation and passage of small and fines chips.

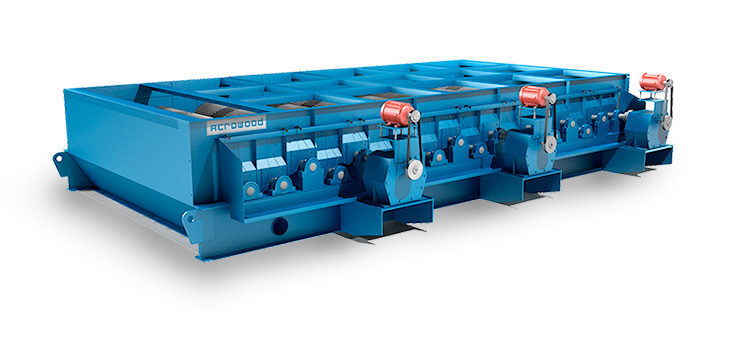

Disc Scalping Screen

The heavy-duty Acrowood Disc Scalper screen is a mill’s workhorse for removal of gross oversized wood pieces, eliminating material handling problems and downstream damage to wood processing equipment.

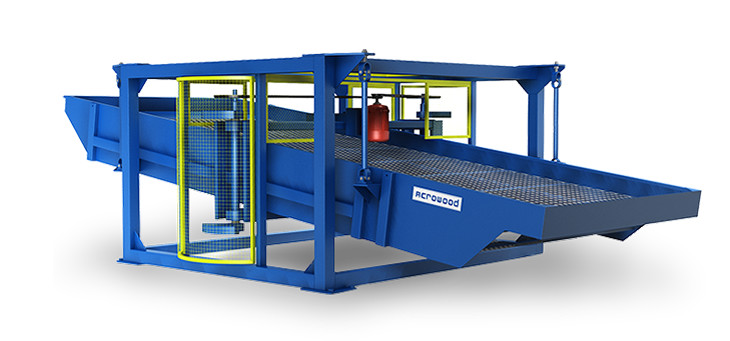

Dual Drive Suspended Rotary Screen

Acrowood’s Rotary Screens are unique in the market with dual drives that leave the screening deck clear for high capacity screening. Easy maintenance and a superior design set this screen apart.

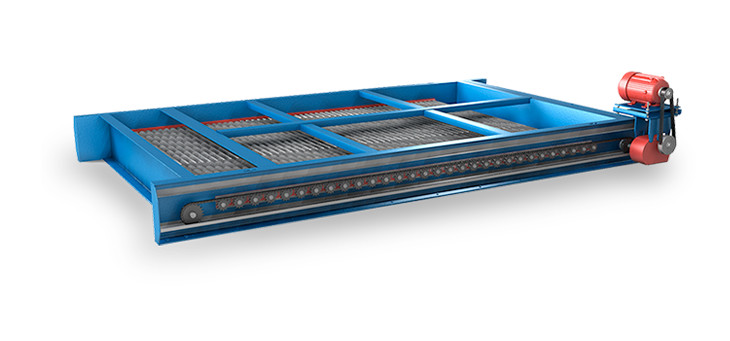

DiamondRoll Screens

Acrowood make the most advanced Roll Screens on the market

The Roll screens feature a textured roll surface that allows the easy passage of fines or particles as the roll turns. Adjacent rolls are spaced so that only the surface-captured fines can pass between them. The active environment which takes place in the space between rolls (nip) allows the pin chips to continually pick

the surface of the rolls clean.

The process of cutting knurl patterns on rolls produces a surface on the shaft which is like a series of pyramids. The tips of the pyramids can be pointed or flat. The height of the pyramid, or the depth of the space between them, represents the capture dimension of the shaft itself, the IRO (inter-roll opening) of the nip is the clear spacing between two effectively cylindrical shafts.

Three factors affect the overall performance of a roll screen. These are knurl depth, IRO (inter-roll opening), and roll speed. Knurl depth is the most important because the overall dimension of the depth of the valley is such a dominating factor in controlling the capture characteristic of the shaft itself. Inter roll opening is second, as this is the dimension that excludes the thin woody particles from passing with the fines. Pin chip loss can be strongly affected by IRO. Roll speed has a role to play by ensuring the materials are fluidized on the screen surface, and are moved briskly from infeed to discharge, but are not sped along so quickly that the fines fail to contact the screen surface.

DiamondRoll™ Thickness Screens

The principle of operation of this unique screen lies in the use of solid shafts, or rolls. These rolls move and agitate a mat of chips as they are fed from the infeed of the screen, letting the smallest chips pass between the shafts first.

DiamondRoll™ Fines Screens

Acrowood was the first in the world to bring roll screens to the industry. Today, hundreds of DiamondRollTM* Fines Screens are in operation worldwide, helping mills retain valuable fiber while removing fines.

DiamondRoll™ Particle Screens

The Acrowood DiamondRollTM* Particle Screen was specially designed to address the special needs of screening sawdust and fine particulates for the manufacture of particleboard and similar products.