SCREENING

DiamondRoll® Thickness Screens

Selective screening & chip removal

Acrowood DiamondRoll® Thickness Screen

Chip Thickness Screening is based on the ability of a screen to selectively remove only those chips that are too thick for the pulping process. Many screens have been used in an attempt to achieve this separation and none has succeeded like the DiamondRoll® Thickness Screen.

Why Leading Mills Trust Acrowood

For over a century, Acrowood has partnered with the world’s top pulp producers to deliver unmatched performance in chip screening. Our DiamondRoll® Thickness screening technology reflects decades of engineering evolution—designed, built, and continually refined for the real demands of mill operations.

With precision-machined rolls, proven VIRO adjustability, and rugged construction made in the USA, Acrowood equipment is engineered to perform consistently, day after day, year after year. Our commitment doesn’t stop at delivery—we provide expert consultation, field support, and long-term partnership that keeps your line running at peak efficiency.

This is more than equipment. It’s experience, reliability, and results—built into every screen we make.

DiamondRoll® Thickness Screen Features

- Most accurate chip thickness screen on the market

- Highly accurate selectivity retained in every installation over years of reliable operation

- Changing thickness targets easily achieved with simple, on-site shim changes

- Roll surfaces are hard chromed for long wear life

- Highest overthick removal efficiency of any screen type

- Maximizing your natural resources

- Scale-able based on the need and type of application (Large or small units available)

- Obtain a higher yield of pulp from raw materials coming in, resulting in immediate savings

How It Works

The principle of operation of this unique screen lies in the use of solid shafts, or rolls. These rolls move and agitate a mat of chips as they are fed from the infeed of the screen, letting the smallest chips pass between the shafts first.

Gradually the larger chips are concentrated on the surface of the rolls, until they are finally discharged off the end. In the nip between the rolls is a gap of free space that lets the acceptable chips fall through. The distance in this gap is what makes all the difference!

Getting The “Good” Chips

For most pulping processes a maximum allowable chip thickness is between 8 and 10 mm. This means that chips larger than 8 mm must be sorted out of the mass of chips that make the feedstock for the pulping process, and treated separately to make them acceptable.

Chips between 2 mm and 8 mm are generally considered to be “good” chips, or Accepts, but larger chips result in high levels of knotter rejects in the pulp mill, and reduce pulping efficiency. Accurately separating these large chips is critically important to the economic success of the pulping process.

Superior Engineering

VIRO Makes the Difference! What makes this screen so special? Variable InterRoll Opening (VIRO) technology! The ability to set the distance between the shafts to virtually any opening needed is a feature unique to the DiamondRoll Thickness screen. The drive system, slotted side frame, bearing block supports, and machined DiamondRoll shafts all fit together in one seamless system of strength, selectivity, and performance. No other screen matches it in terms of efficiency or performance!

Shaft spacing is adjusted by changing shims between bearing blocks in the side frame of the screen. The bearing blocks for each shaft run in a slot cut into the frame, separated by these “shim” spacers.

Using spacers between the blocks sets the spacing between the rolls. If a larger opening is needed, additional shims can be added. If the rolls need to come closer together, a thinner shim is used. In either case it is a simple and quick matter to alter the screen, and can be done in a few short hours, without the need of special tools.

Machine Basics

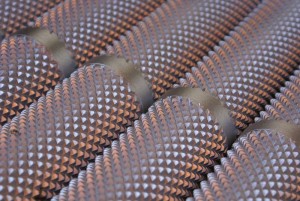

Each DiamondRoll roll starts out as a solid alloy steel shaft. It is machined to a precisely specified diameter, cut with the diamond pattern, has the chambered shaft end added at the end, and is finished with a journal on each end to mate with the specially designed housing and bearing. The entire surface is hard chromed for long service life.

The drive is a loop chain design using lube-free chain and special sprockets. This highly efficient design makes it possible to keep the drive simple and maintenance free, yet drive the longer and higher capacity screens needed by mills today.

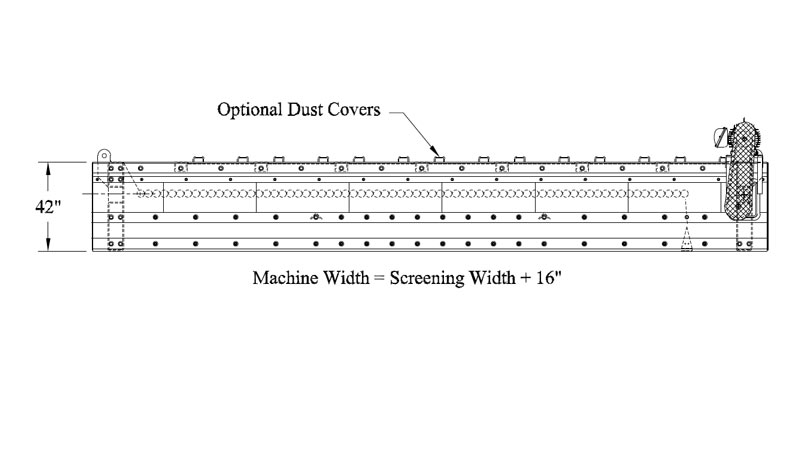

The side frames are steel plate with aluminum drive enclosures. Dust covers are provided. Screens are shipped either fully assembled, or they can easily be assembled in place to save on installation costs.

Integrated Scalping Screen

It is possible to include a scalping screen section after the thickness screening section. The shafts used here are typically cut with a deeper knurl pattern, and set 20 to 30 mm apart. This section rejects large strings, knots, and cards present in the chip flow, protecting the overthick chip processing equipment that follows.

| Roll Width | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| width (in) | ||||||||||||||||||

| # of Rolls | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) | Motor (HP) | Weight (tons) |

| 40 | 10 | 9.5 | 10 | 10.5 | 15 | 11.5 | 15 | 12.5 | - | - | - | - | - | - | - | - | - | - |

| 50 | 15 | 11 | 15 | 12.3 | 15 | 13.5 | 15 | 14.8 | 15 | 16 | - | - | - | - | - | - | - | - |

| 60 | 15 | 13 | 15 | 14.3 | 15 | 15.5 | 15 | 16.8 | 15 | 18.3 | 15 | 19.5 | 20 | 21.3 | 20 | 22.3 | 20 | 23.8 |

| 70 | - | - | 15 | 16.3 | 15 | 17.8 | 15 | 19.3 | 20 | 20.8 | 20 | 22.3 | 20 | 23.8 | 20 | 25.3 | 20 | 26.8 |

| 80 | - | - | - | - | 15 | 19.8 | 20 | 21.4 | 20 | 23.0 | 20 | 24.8 | 20 | 26.3 | 20 | 28.0 | 20 | 29.8 |

| 90 | - | - | - | - | - | - | 20 | 23.8 | 20 | 25.6 | 20 | 27.5 | 20 | 29.3 | 20 | 31.1 | 25 | 33.1 |

| 100 | - | - | - | - | - | - | 20 | 26.0 | 20 | 28.0 | 20 | 30.0 | 20 | 32.0 | 25 | 34.0 | 25 | 36.0 |

| 110 | - | - | - | - | - | - | - | - | - | - | 25 | 32.9 | 25 | 35.1 | 25 | 37.3 | 25 | 39.9 |

| Roll Width | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.0 | 3.4 | 3.7 | 4.0 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| width (m) | ||||||||||||||||||

| # of Rolls | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) | Motor (KW) | Weight (mt) |

| 40 | 7.5 | 9.7 | 7.5 | 10.7 | 11 | 11.7 | 11 | 12.7 | - | - | - | - | - | - | - | - | - | - |

| 50 | 11 | 11.2 | 11 | 12.4 | 11 | 13.7 | 11 | 15.0 | 11 | 16.3 | - | - | - | - | - | - | - | - |

| 60 | 11 | 13.2 | 11 | 14.5 | 11 | 15.7 | 11 | 17.0 | 11 | 18.5 | 11 | 19.8 | 15 | 21.6 | 15 | 22.6 | 15 | 24.1 |

| 70 | - | - | 11 | 16.5 | 11 | 18.0 | 11 | 19.6 | 15 | 21.1 | 15 | 22.6 | 15 | 24.1 | 15 | 25.7 | 15 | 27.2 |

| 80 | - | - | - | - | 11 | 20.1 | 15 | 21.7 | 15 | 23.4 | 15 | 25.1 | 15 | 26.7 | 15 | 28.4 | 15 | 30.2 |

| 90 | - | - | - | - | - | - | 15 | 24.1 | 15 | 26.0 | 15 | 27.9 | 15 | 29.7 | 15 | 31.6 | 18.5 | 33.7 |

| 100 | - | - | - | - | - | - | 15 | 26.4 | 15 | 28.4 | 15 | 30.5 | 15 | 32.5 | 18.5 | 34.5 | 18.5 | 36.6 |

| 110 | - | - | - | - | - | - | - | - | - | - | 18.5 | 33.4 | 18.5 | 35.7 | 18.5 | 37.8 | 18.5 | 40.5 |

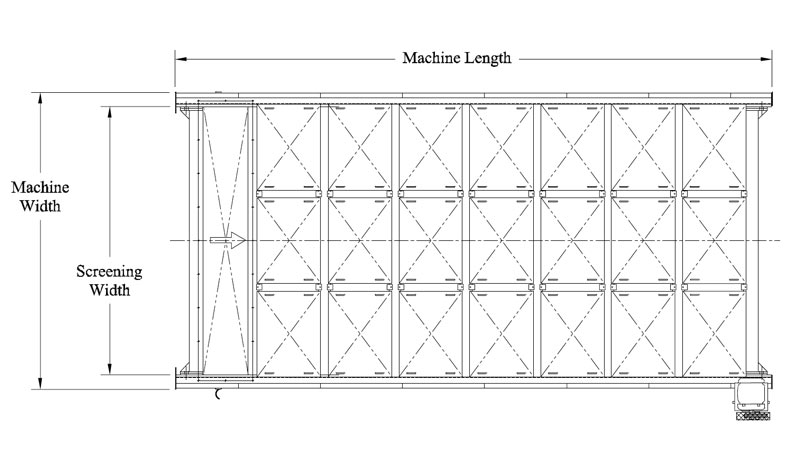

DiamondRoll Thickness Screen Diagram of Machine Length & Width and Screening Width

DiamondRoll Thickness Screen Dimensions Diagram with optional Dust Covers

The DiamondRoll® Thickness Screens brochure

Request the DiamondRoll thickness screen machine brochure provided to you in PDF format for easy reading and printing.

Case Study: Primary Thickness Screening, Efficiency and Chip Size Distribution

The big advantage of the DiamondRoll screen is that the solid steel rolls are set in the frame of the screen in such a way that the opening dimension is highly uniform. Since the shafts don’t vibrate and are not subject to bending or damage, the IRO is consistent over the operational life of the screen.

Case Study: Pulping System Sensitivity to Chip Quality

What this means is that the rate limiting dimension of the chip is its smallest dimension, which is its thickness. This was the critical discovery that resulted in Chip Thickness Screening (CTS), and the resultant rush to install CTS systems in every Kraft mill in the world.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.