SCREENING

DiamondRoll® Particle Screens

Selectivity when and where you want it

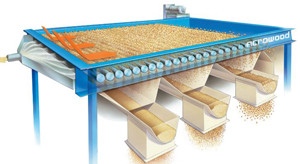

Acrowood DiamondRoll® Particle Screens

The Acrowood DiamondRoll® Particle Screen was specially designed to address the special needs of screening sawdust and fine particulates for the manufacture of particleboard and similar products.

Why Leading Mills Trust Acrowood

For over a century, Acrowood has partnered with the world’s top pulp producers to deliver unmatched performance in chip screening. Our DiamondRoll® Particle screening technology reflects decades of engineering evolution—designed, built, and continually refined for the real demands of mill operations.

With precision-machined rolls, proven VIRO adjustability, and rugged construction made in the USA, Acrowood equipment is engineered to perform consistently, day after day, year after year. Our commitment doesn’t stop at delivery—we provide expert consultation, field support, and long-term partnership that keeps your line running at peak efficiency.

This is more than equipment. It’s experience, reliability, and results—built into every screen we make.

DiamondRoll® Particle Screen Features

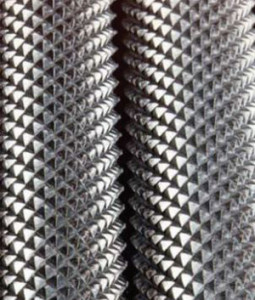

This screen has larger diameter shafts than the typical fines screening version. As a result, materials spend more time in the nip, leading to better screening of small particles. The roll surface patterns are often smaller and the Inter-Roll Opening has tighter spacing to accommodate the sorting of small and fine fractions.

- Segregate varied particle fractions within the same screen bed by employing a wide variety of knurl sizes

- Easily sealed for dust tight operation

- Low profile screen frame for simple installation

Face And Core On The Green End

Mills have found that effectively screening the green end materials, before milling and refining, allows a significant portion of the raw material to by-pass this step. This means that fiber destined for both face and core fractions remains intact and is not unnecessarily beaten and shortened. The result is a stronger final product, less front-end material handling, less horsepower used, and better control of the face and core fractions.

Where It Can Be Used

The DiamondRoll screen can be used on the dry end to produce face and core fractions ahead of the blender, or final forming machine.

Regardless of your mill’s forming method, the DiamondRoll Particle Screen can help you better sort and prepare your particulate fractions, saving handling time and expense, reducing resin use, improving finished board properties, and saving your mill money.

Selectivity When And Where You Want It

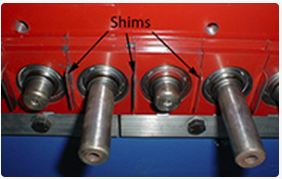

The Variable Inter-Roll Opening (VIRO) allows the spacing between the shafts to be independently adjusted at any point along the screen, increasing selectivity. A smaller opening at the infeed or at the discharge end of the screen may have advantages. In the DiamondRoll® VIRO Screen, all gaps in the screen can be adjusted individually. Achieving varied roll spacing is as simple as changing the shims between adjacent bearing blocks.

Development Center

Contact Acrowood today to schedule a trial on the fully-featured DiamondRoll Particle or DiamondRoll fines test screen, both maintained in the Acrowood Development Center. See for yourself what this innovative and proven technology can do for your mill.

Adaptability

Variable Inter-Roll Opening (VIRO) allows the spacing between the shafts to be set to meet the specific needs of the application, but then to be easily adjusted if material quality changes, or if process advantages develop for different openings. Shaft spacing is adjusted by changing shims between bearing blocks in the side frame of the screen. Shims between the bearing blocks set the spacing between the rolls. If a larger opening is needed, additional shims can be added. If the rolls need to come closer together, a thinner shim is used. The IRO and the speed of the shafts can be independently controlled and work together to fine tune screen performance.

Success Is In The Rolls

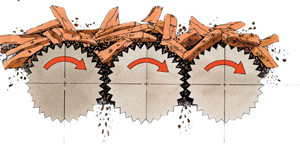

Chips travel across a series of parallel, rotating rolls machined from solid alloy steel. As these diamond-patterned rolls rotate, fines migrate into the space between the diamond tips and are rejected through the Inter-Roll Openings (IRO).

Pins and chips larger than the opening are carried over the screen’s surface and off the end. Using solid, alloy steel shafts helps to maintain the straight and constant nip opening. High IRO accuracy is the key to the screen’s efficiency.

Dust Tight Conditions Built-In

The screen frame completely encloses the chips and fines. Steel dust covers are set into the frame above. Chutework connects solidly to flanged openings, making the entire system dust-tight.

Simple, Lubrication-Free Drive and Bearings

Continuous loops of chain drive all shafts. A single motor located at the discharge end of the screen drives the chain. The continuous loop chain drive makes the VIRO feature possible, since the chain pitch does not limit the position of the shafts.

Oil lubrication has been eliminated from the side frame, since both the chain and the bearings are lubricated for life. The chain is a high-strength sintered bushing roller chain, with lubricant incorporated into the structure of the bushing itself. The bearings are grease-lubricated ball bearings, sealed at the factory, and require no lubrication in the field. Both are built with long service life and minimal maintenance requirements in mind.

Vibration-Free Operation

Rotating rolls create agitation – a tumbling, mildly abrasive action. Turning of the rolls does not cause the bouncing and shaking associated with rotary screens, or screens that rely on the beating of hole-filled rubber mats.

The DiamondRoll Screen comes complete with zero-speed sensors; no vibration or excessive motion sensors are required. No vibration or lateral loading is placed on building structure.

More Acceptable Strands For Board Production

This photograph shows the <6 mesh, >14 mesh fraction generated by classification of the DiamondRoll Accepts. While this material was somewhat shorter than the same fraction segregated from the Trillium Accepts, the particles were still quite long and appear to be acceptable for board production.

Separation Of Strands For Fuel

The material passing through the DiamondRoll VIRO Screen that classified as being less than 6 mesh in size but greater than 14 mesh was distinctly different than this fraction in either of the accept flows. The particles were much shorter and would offer much less strength when incorporated into a panel. This fraction may be more suitable for fuel than board production.

The DiamondRoll® Particle Screens brochure

Request the DiamondRoll particle screen machine brochure provided to you in PDF format for easy reading and printing.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.