The Acrowood Batch Rotary Debarker High Capacity Whole Log Debarker with Bottom Discharge

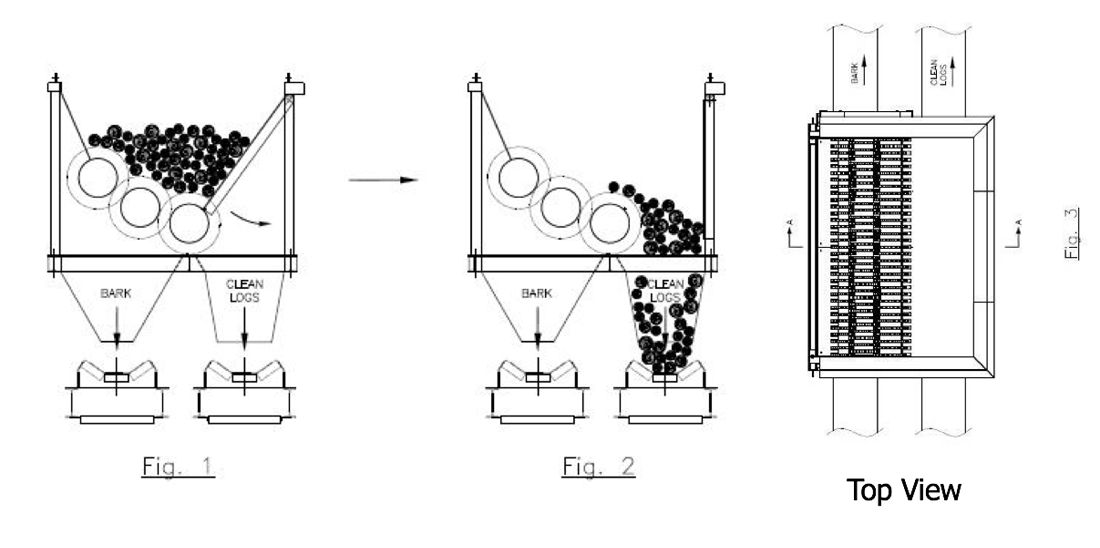

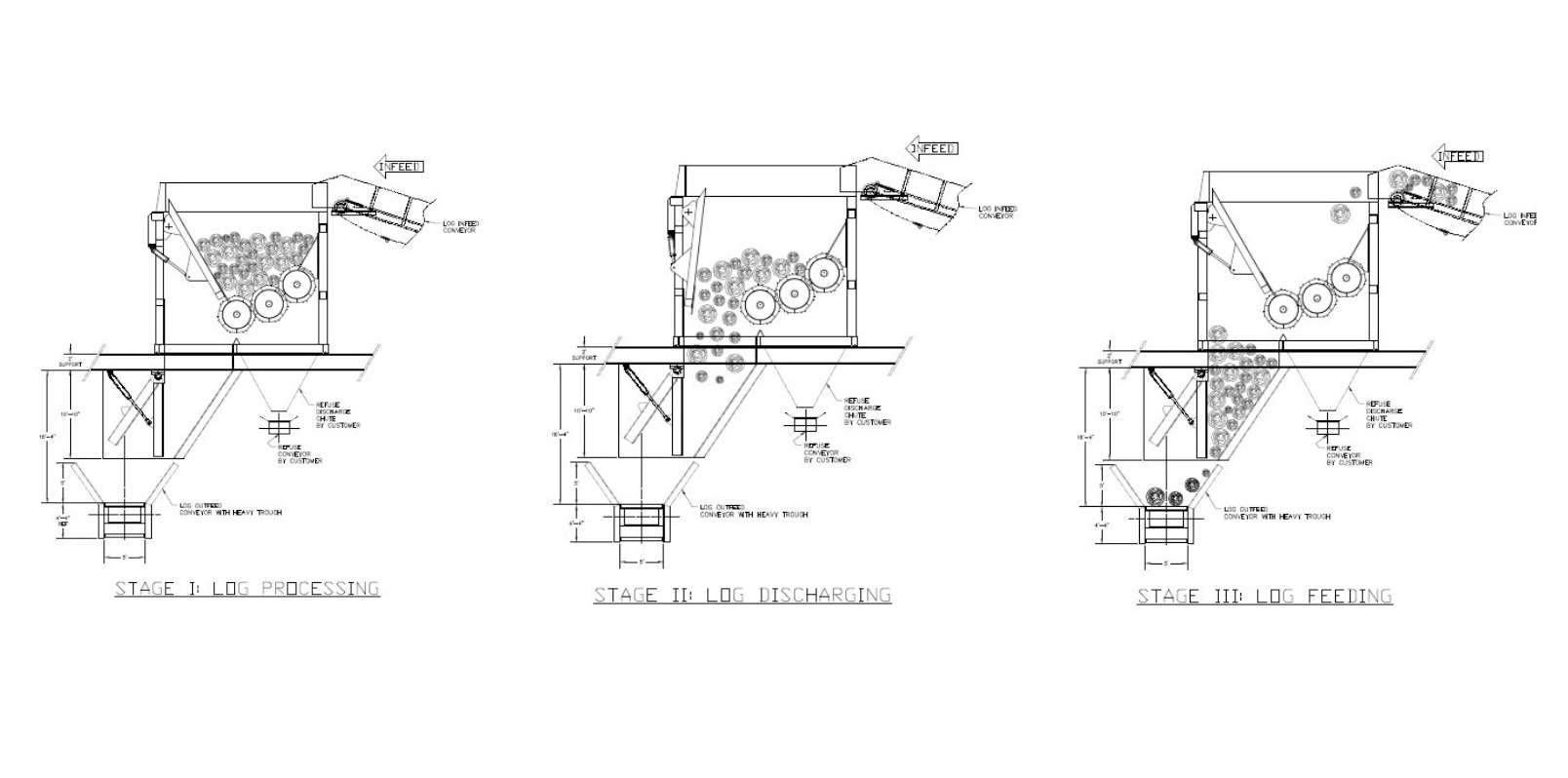

The Batch Rotary Debarker is proven and identical to the Continuous Rotary Debarker, but features the newly added, patent pending, bottom discharge. This debarker takes bundles of logs that can be run in batches, with specific debarking timings for different seasons and wood types.

Batch Debarking Machine

- Same log flow characteristics as a drum debarker

- Stringy bark, crooked, small diameter, or contaminated wood easily processed

- Low loss of usable fiber

- Highly effective debarking

- Low energy requirements and relatively low noise levels

- Open bottom design passes bark readily to discharge conveyor

- Effective debarking of frozen wood without requiring de-icing

Acrowood Newly Invented Whole Log Debarking Bottom Discharge Style

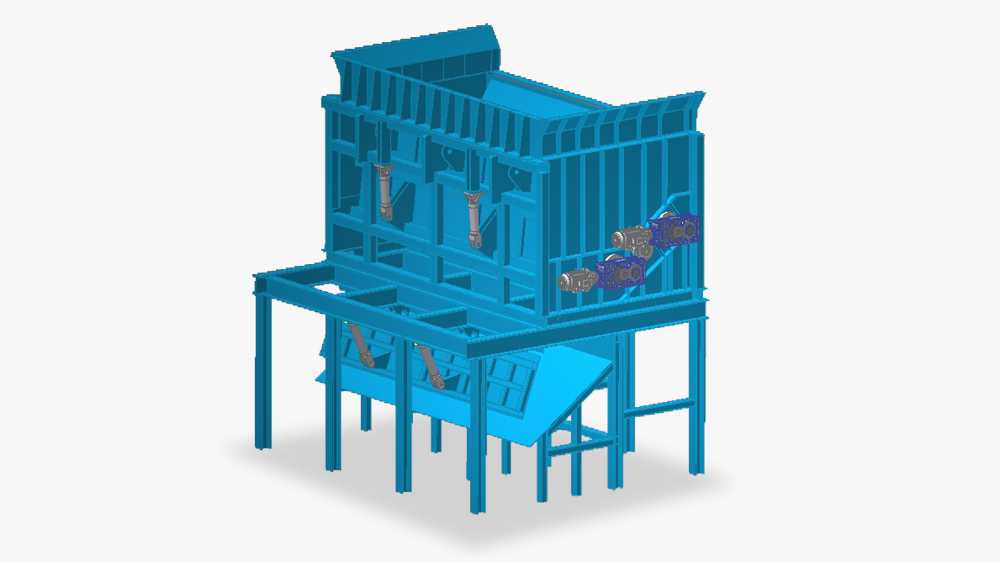

Batch Debarker In Operational Position

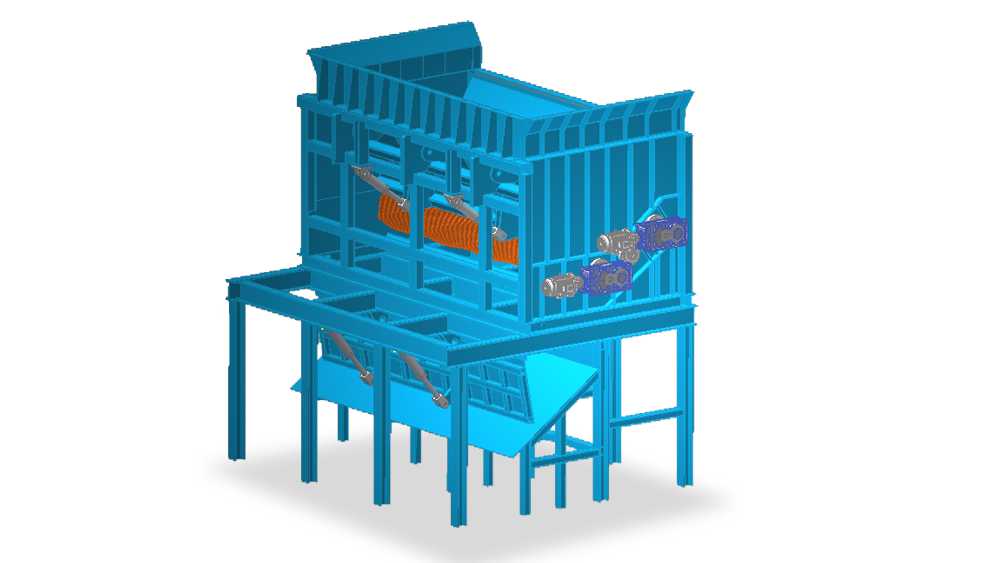

This perspective model view of a batch debarker has the upper discharge door closed. The closed upper door signals the position in which the debarker is operational and batches of logs are cycling in the machine.

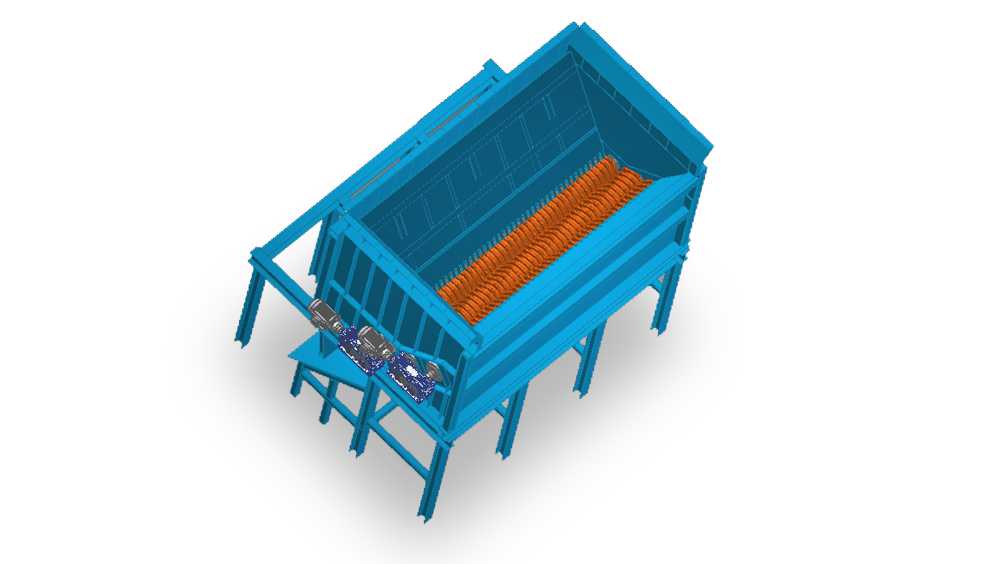

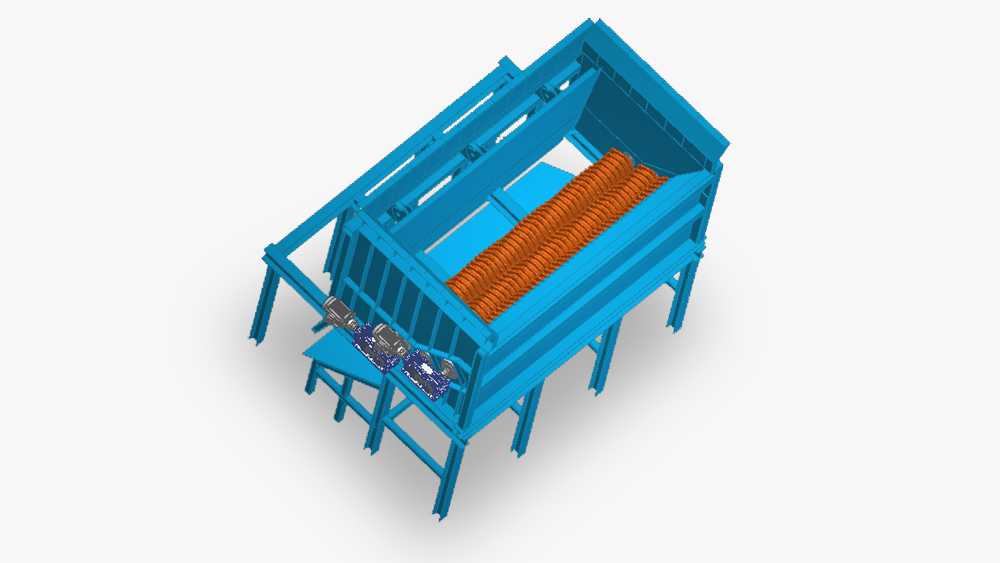

Top View Door Closed of Debarker

The top view shows the upper hatch door closed of the batch debarker, exposing the live bottom array that pulls the bark gently from the logs and passes the bark and fiber through into a catch conveyor.

Batch Debarker Discharge Door Open

This perspective view of the batch debarker shows the upper discharge doors open. The open upper doors signals the position in which the debarker is in discharge mode allowing the logs to fall though.

Top View Door Open of Debarker

The top view shows the batch debarker upper hatch door open, allowing the logs to fall through this design alleviates the need for special handling equipment.

Debarker Operation

- Peak design rate – 300 gtph

- Catch up surge rate – 330 gtph

- Bark specification – less than 1% remaining by weight in wood room accept chips, often reaching <0.5%

- White wood loss – 3% or less on an annual average basis

- Bottom discharge which overcomes the cost of handling equipment required by side discharge approaches. (Log Discharge Transfer Deck plus Singulator, Step Feeder or Log Loader to feed Logs into Chipper Infeed Conveyor)

- The issues of detangling random length wood in singulation after discharge which is common with side discharge approaches

Debarker Suitable Applications

- Pulp Mills

- Satellite Chip Plants

- OSB Plants

- Pellet Plants

- Shavings Mills

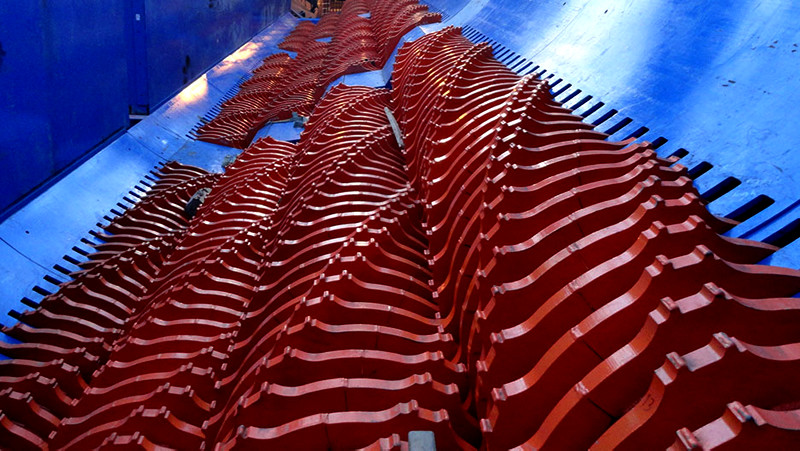

The live-bottom rotor design has no plates between rotors to restrict the removal and passage of bark and sand. This results in maximum capacity for the foot-print required. Simple chuting below and a conveyor provide bark removal below the debarker.

Robust, heavy-duty design

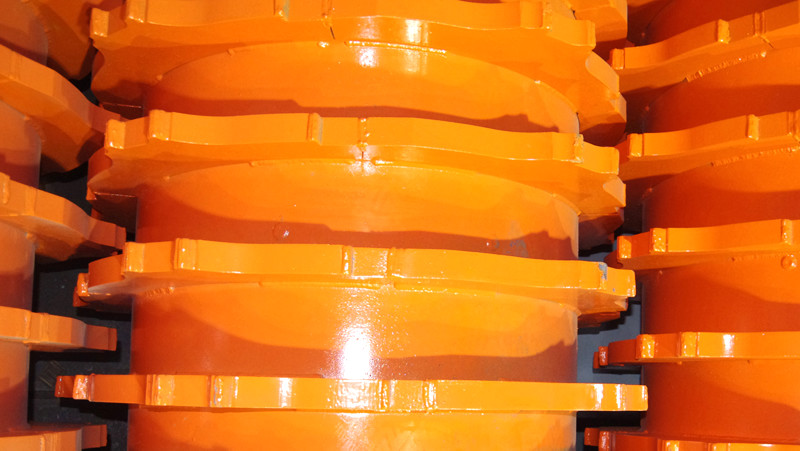

- Acrowood large diameter, thick-walled, rotor tubes which create a large section modulus for outstanding rotor stiffness and strength.

Mill Feedback on Rotary Debarking

- Much quieter than old drum debarker

- Significantly improved up-time

- Significantly improved debarking in all operating conditions

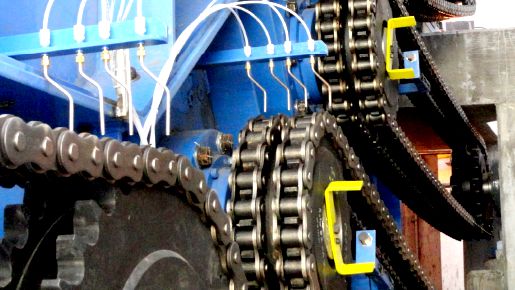

Whole log debarker drive details

Individual rotors are driven using doubled RC-240 chain from foot mounted reducers.

Live bottom rotor array

The live floor design handles both large and small diameter stems very efficiently. The floor of the entire debarker is in motion, so stems have no dead space to sit and avoid rotation.

Specially Designed Rotor and Teeth Profile to suit application due to Log Sizes Changes

- Acrowood’s rotors have discs which interleave creating a tight IFO that keeps small wood pieces above the rotor array and improves white wood recovery.

Live floor design

- Our fully live floor design handles stringy bark very well, with no fixed plate to restrict passage of bark out of the debarker.

Advantages of the bottom discharge style

Eliminate Transfer Deck

Transfer Deck otherwise known as Strander Feeder Deck required by legacy side discharge method of Batch style debarking

Eliminate Step Feeder, Log Loader or Singulator

Required for legacy side discharge debarkers.

Less Space Required

The rotary batch debarker takes up less space compared to legacy discharge method.

See Smooth & Consistent Flow

Downstream Wood Chipper will see a smooth and consistent flow of debarked logs which will guarantee the chipper capacity while the conventional side discharge method has issue frequently.

The Rotary Batch Debarker brochure

Request the batch debarker brochure in PDF format for easy reading

Case Study: Pulping System Sensitivity to Chip Quality

Debarkers are the first machine in the pulping process that strips away the bark, sand and grit preparing them to be turned into acceptable sized wood chips by a whole log chipper.

Case Study: Rotary Debarking – A Process Description

Rotary debarking has fast become a preferred method for multiple stem continuous feed wood debarking and processing for forest industries.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.