CHIPPING

Veneer Chipper and Feedworks

Convert waste veneer into usable chips

Veneer Chipper

Feedworks

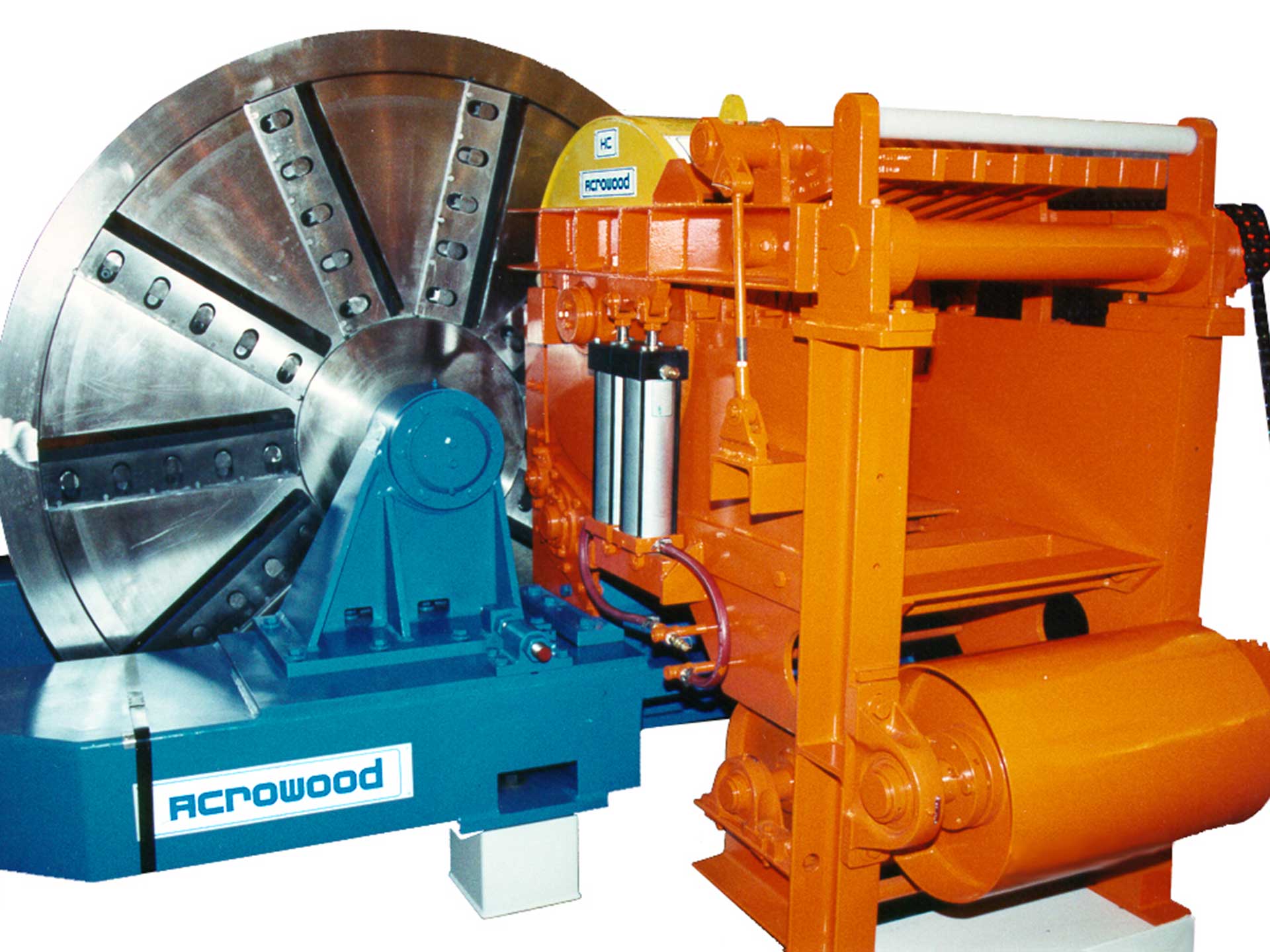

Acrowood Veneer Chipper and Feedworks

The Acrowood Veneer Chipper-Long and High Capacity Feedworks transforms waste veneer into high-quality chips that can be sold or used for multiple purposes. Dramatically increase your yield of usable fiber in converting waste veneer to chips by using an Acrowood VCL and HC Feedworks, tested and proven for over 40 years.

Veneer Chipper & Feedworks Features

- Higher yield of usable chips produced in the Acrowood VCL Veneer Chipper and HC Feedworks than any other veneer chipper

- Rigid, high strength chipper base

- Stable and strong bearing pedestals facilitate adjustment of the thrust bearing

- Chip impact and damage is reduced by extra deep chipper casing

- Less power requirements with pivoting arm design: weight of the rolls provide the cracking force and reduces hydraulic pressure needs

- Veneer held stable for the highest chip quality by crush roll and fingers of the high-capacity feedworks

Produces Long Chips

The Acrowood Veneer Chipper is specially designed to produce chips from waste veneer. The design of the chipper disc, arbor, and base produces an ideal arrangement so that the knife passes in the correct orientation relative to the anvil and anvil base. This chipper is not suitable for chipping cores or other forms of waste wood, as the knife and anvil arrangement is wrong for these other applications.

Veneer Chipper and Feedworks Attached (in photo)

Ideal Knife & Anvil Arrangement – Produces Long Chips

The Long designation in the VCL name relates to the ability of the chipper to produce chips as 1-1/4 inch with the 8 knife disc. Chip length is set both by the knife projection above the disc (which is a function of the thickness of the knife wedge), and by the feed speed determined by the feedworks. Longer chips produce fewer fines and pins, a critical concern when chips are being used for pulp production.

Both chipper bearing pedestals and the chipper anvil base are re-buildable and can be reconditioned in our shop.

Durability & Long Service Life

Casting the disc is a more expensive way to make this critical part, but allows the designers to place just the right amount of steel in across the back of the disc, ensuring the stiffest and strongest possible part. The cast steel disc is fully machined to accept all necessary hardware. The front of the chipper is covered with wear plates and wear resistant parts, including the face mounted knives, special hardened and high strength bolts, and wear plates. The leading edge of the knife wedge is hard surfaced for long service life.

Cast Steel. Wear Resistant Parts

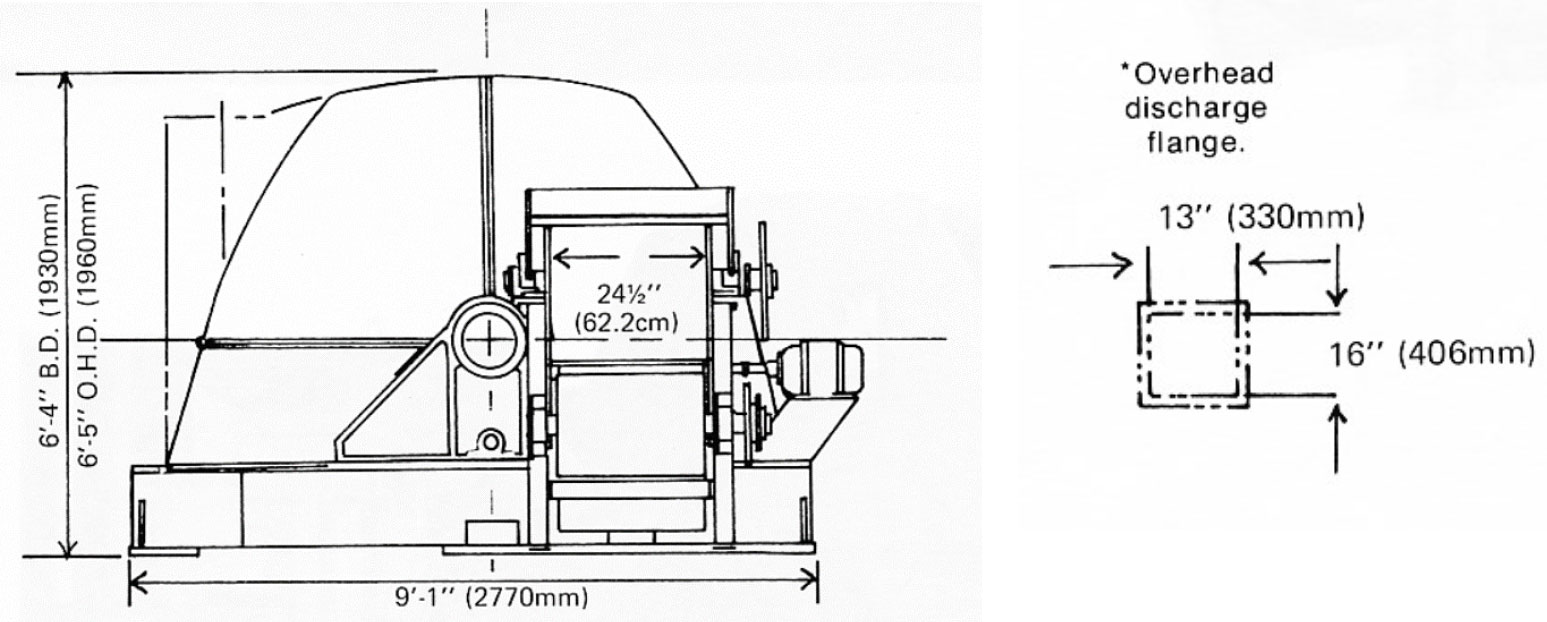

Fabricated pedestals designed specifically for this purpose support the front and rear bearings. They hold the disc securely during all aspects of chipping. The disc and casing can be either bottom or overhead discharge. Blowing components (piping, cyclone, elbows, etc.) are available as options.

Feedworks

Feeding System Eliminates Problems

High Capacity Feedworks

Loose veneer can create an awful mess at the chipper unless it is compressed and held down until the actual chips are formed. The Acrowood HC Feedworks incorporates years of veneer chipping experience and design improvements, and represents the best available technology in this important area. Surges and loose veneer stacked randomly on the conveyor that causes other systems problems is not a problem for the Acrowood HC Feedworks.

Fingers Secure & Guide Veneer

A set of aluminum “fingers” passes through the turning roll. These fingers serve both to guide the veneer into the compression roll correctly on the infeed side, but more importantly, they hold the veneer down securely right up to the point of chipping. The veneer sheets are not allowed to jump or twist during the cutting process, so that every chip is as perfect as it could be. The special shape of the fingers holds the veneer, and the aluminum construction prevents damage to the chipper.

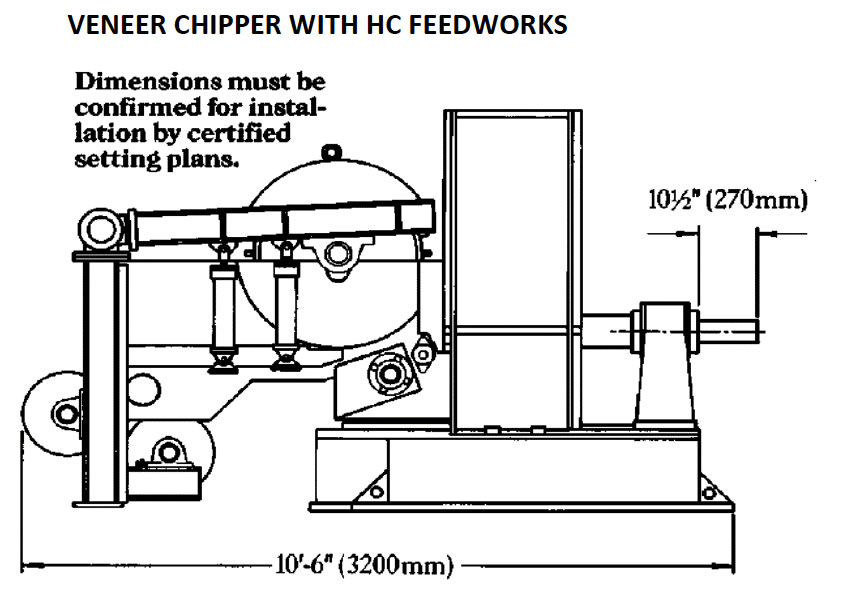

Belt Speed, Disc RPM

The feed belt conveyor threads through the base of the feedworks and forms an integral part of the feeding system. The speed of the belt and the rotation speed of the chipper disc are critical in forming the proper length chip. By providing the belt driving mechanism, the Feedworks insures that the belt speed is correct.

Overhead Compression Roll

The overhead compression roll is driven by the same motor, and is synchronized with the belt speed, so that there is no shearing or tearing of the veneer prior to chipping.

Hinged Pivot

The roll is hinged and can pivot the Feeding system which eliminates problems when the veneer load is great, while still providing the compression force needed to hold the veneer stable.

Adjustable Pressure

Two cylinders with adjustable pressure provide additional compression force on this roll, and damp the movement for smooth operation.

We Can Retrofit Older Chippers

We can retrofit older chippers The HC Feedworks can be retrofit on an older chipper.

Please contact Acrowood for a free evaluation of your chipper’s operation.

Applications

- Chip Plants

- OSB Plants

- Pellet Plants

- Pulp Mills

- Sawmills

- Shavings Mills

Engineered Drawing of Veneer Chipper and Feedworks

Feedworks: Drive - 10 HP, Motoreducer; Speedroll - 3 HP, 900 RPM motor | Infeed Belt Speed (FPM)

| Knives | Spout Size (in) | .75 (in) Chips (FPM) | 1 (in) Chips (FPM) | 1.5 (in) Chips (FPM) | Capacity (uph) | Motor (HP) | RPM |

|---|---|---|---|---|---|---|---|

| 8 | 7 x 24.5 | 249 | 331 | N/A | 25 | 150 - 200 | 514 |

The Veneer Chipper and Feedworks brochure

Request the veneer chipper and feedworks machine brochure in PDF format for easy reading and printing.

Case Study: Chipper Upgrades and Replacements

Acrowood has been fortunate to have been involved in the redesign and upgrade of several chippers, both domestically and overseas. Some of these stories involve changes that have been relatively simple, and some have been fairly complex, involving replacement and redesign of fundamental components of the chipper.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.