CHIPPING

Chip Slicer

High capacity precision wood chip slicing – low cost, long life.

Acrowood Chip Slicer

In installations worldwide, Acrowood Chip Slicers produce fewer pins and fines while slicing at higher capacities and smaller gap settings. The Chip Slicer is designed to reduce a chip in its size from overthick to acceptable thickness. This machine has been serving pulp mills for over 35 years; reducing overthick production by greater than 95%.

Chip Slicer Features

- Inner and outer rotors are driven at different speeds to properly orient overthick chips for accurate slicing to target thickness

- High efficiency and heavy-duty gear drive

- Shear pin coupling

- Slicing accuracy maintained with solid one-piece knife and anvil rings for close knife-to-anvil tolerance

- Fabricated anvil rotor results in longer life

- Low horsepower requirements and high performance

- In installations worldwide, Acrowood Chip Slicers produce fewer pins and fines while slicing at higher capacities and smaller gap settings.

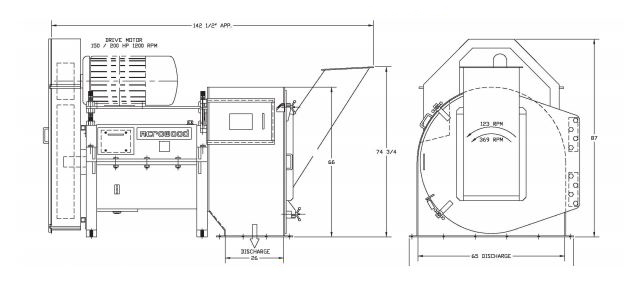

Precision Spur Gears

Oversized, precision-ground spur gears are submerged in a 7″ deep, 35-gallon oil bath kept in circulation by the gears. This robust design is proven by decades of trouble free operation.

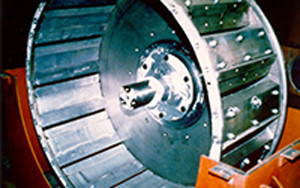

Knife Ring

The knife ring assembly has knife pockets machined out of a solid steel ring.

Even Distribution And Orientation

The chip infeed chute, knife rotor and anvil rotor design combine to produce more even chip spreading and better chip orientation. The central chip infeed chute directs chips evenly along the knives and anvils, for the prevention of uneven knife wear.

Fabricated Rotor For High Impact Resistance

A fabricated design, rather than cast, results in more rigid construction, tighter internal tolerances, greater damage resistance, and longer life. The robust Open Area anvil rotor provides optimum chip orientation and durability — making it the most cost-effective rotor available.

More Accurate Slicing

Our solid steel, one-piece ring permits accurate knife positioning and assures close knife-to-anvil tolerance. The tighter tolerances and greater rigidity of the solid knife rotor mean fewer pins and fines produced and reduced horsepower requirements.

Durable Drive Components

For impact resistance and long term durability, special gears were designed and built just for the slicer. These precision-ground spur gears are far heavier and larger than the gears used in other slicer drive systems. These custom gears are less susceptible to wear and tooth breakage. Our gear design and precision grinding also means less friction losses and quieter operation. The over-sized gears are submerged in a 7” deep, 35-gallon oil bath kept in circulation by the gears. The oil cools and lubricates the components. No oil pumps or cooling fans are needed. With lubrication reaching all components, the drive system runs cool and quiet for long life.

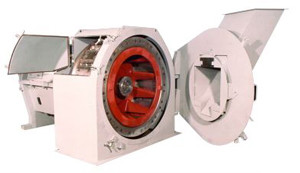

Designed For Fast, Easy Maintenance

Acrowood’s Chip Slicer design incorporates a wide side access door for quick, easy knife changes; a full swing front access door for removal of rotating members; and a sectional gear housing for easy access to the gears and bearings.

The Chip Slicer brochure

Request the chip cracker machine brochure in PDF format for easy reading and printing.

Case Study: Overthick Chip Chip Treatment

The Chip Slicer was adapted and redesigned around the original concept of a knife ring flaker. Any chip that is processed by a Chip Slicer passes between a knife and a gauge plate, each set in such a way as to produce a 6.5 mm thick slice…

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.