A

crowood supplies pulp and paper operations all over the world with the most efficient chipping, screening and debarking equipment. Acrowood has mastered the art of chip processing, every step along the way starting with debarking, whole log chipping, screening, distributing, and cracking.

We will engineer, deliver and set up the ideal machines for your woodyard, whether you are making paper, tissue, container, or fiberboard, you will see why most pulp and paper mills use Acrowood.

Debarking Equipment

Acrowood Debarking machines are custom fitted for your mill, the rotors, discs and spacing are all considered based on the wood species and log diameter. Acrowood has been continually refining and perfecting the craft of debarking for decades. View the Continuous Rotary Debarker and the new Batch Debarker.

Chipping Equipment

Acrowood chipping technology produces the most efficient and highest quality wood chips. Acrowood provides a full line of wood chipping solutions to meet your specifications. Choose from Whole Log Chipper, Slant Disc Chipper, Veneer Chipper & Feedworks, Rechipper, Chip Cracker, and Chip Slicer.

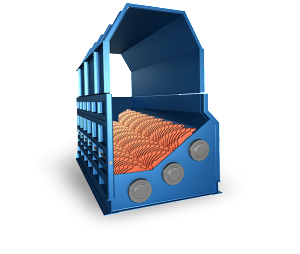

Screening Equipment

Acrowood screening technology reduces downstream processing costs, providing you with low maintenance, very accurate, heavy-duty, high capacity strand, and chip sorting options for your operation. We have a wide variety of screens available such as the Trillium OSB Strand Screen, Disc Thickness Screen, Disc Scalping Screen, Dual Drive Suspended Rotary Screen, DiamondRoll Thickness Screen, DiamondRoll Fine Screen, and the DiamondRoll Particle Screen

Distributing & Separating Equipment

Acrowood develops specialty distribution and separation machinery to enhance your production lines and add even more value to your wood and materials processing. Such as contaminant removal with the Air Density Separator, meter the flow of materials with the Star Feeder and Screw Distributor.