A

crowood is a heavy equipment manufacturer located in Everett, Washington; making forest products equipment since 1892, and serving clients on all continents.

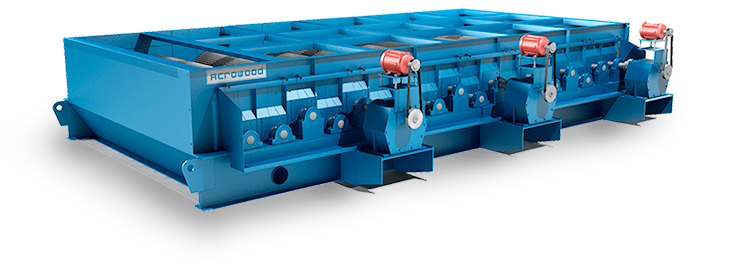

Specializing in large and high capacity machines to screen and clean all sorts of wood chips, sawdust, and shavings; Acrowood serves companies in the panel board, pulp and paper, and sawmilling industries.

We’ve been designing, manufacturing, and selling log chipping, debarking, and screening solutions for 130+ years. The company began as Sumner Iron Works. Sumner flourished in the Pacific Northwest heyday of logging and lumbering, making nearly every type of equipment needed for felling and log yarding, sawmilling, hauling, and log rafting.

View the evolution of Acrowood below.

We think of our history as four ages

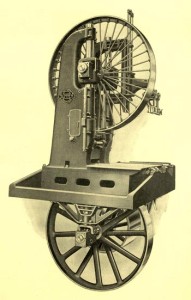

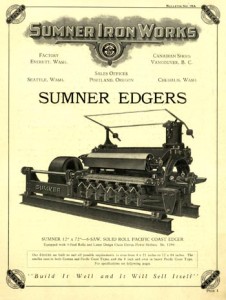

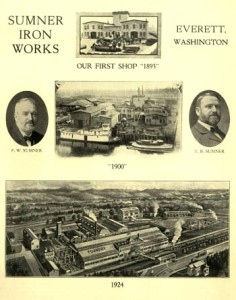

1892–1931 : Bronze Age Sumner Iron Works

• Founded in 1892 (during a depression)

• Flourished in the heyday of logging in the Pacific NW

• Developed a complete line of machines for felling, log yarding, sawmilling, and log rafting

• Grew to have its own foundry making massive cast parts.

1932–1963 : Iron Age Sumner Iron Works

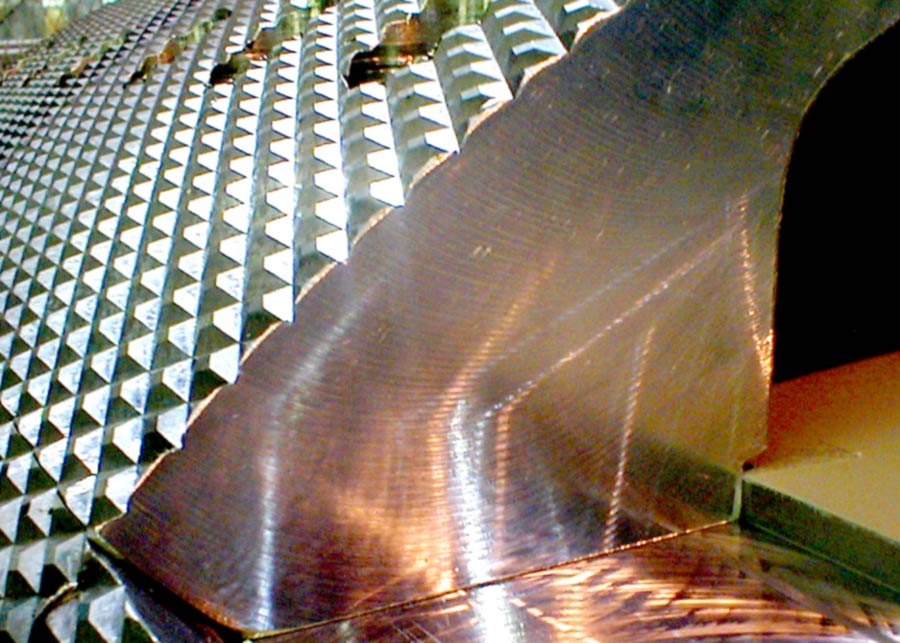

• Developed the 1st helicoid-faced chipper in 1932

• Developed 1st vertical disc, horizontal feed, veneer chipper with powered feedworks

• still the basis of modern designs for chipping waste veneer.

• Weathered the Great Depression

1963–1984 : Silver Age Black Clawson Subsidiary

• In 1963, 71 years after the company was founded, it was acquired by Black Clawson, a world leader in pulp and paper machinery

• As a new subsidiary, it became the focus for its forest products initiative thereby broadening its line of products.

• The Everett subsidiary made the world’s largest whole log chipper (175” diameter disk)

• The Everett subsidiary invented and built the “Bellingham Barker”, the 1st of it’s kind.

1984 – now : Gold Age Acrowood Corporation

• In 1984, the company was acquired and is closely held

• As an independent entity it was freed to pursue R&D

• Acrowood is now the world leader in chip thickness screening and North American leader in wood processing equipment for Pulp Mills and woodyards.

WHERE WE ARE TODAY

ACROWOOD CORPORATION

We continue to innovate and grow

Pioneered and leading the market in Chip Thickness Screening

Continually enhancing our solutions for Chipping, Cracking, Debarking, and Feeding

Our fiscal responsibility enables us to service our customers through all business cycles

ACROWOOD’S MARKET POSITION

In the last 5 years we’ve sold equipment to 425+ locations for 250+ customers in 10+ countries

One half of all chemical-pulp mills in North America have purchased from Acrowood in the last 5 years.

Two-thirds of the top pulp producing mills (by volume) in North America have purchased from Acrowood in the last 5 years.

The majority of chemical-pulp in North America is produced using Acrowood‘s screens, crackers and chippers.

We’ve been doing repeat business with our customers for decades and decades.

All while seeing our competitors merge, be acquired, and fold.

ACROWOOD’S ENGINEERING

World class team of mechanical and civil engineers.

We’ve been issued numerous patents since our inception (14 as Acrowood).

Have 2 new patents pending in 2015 for rotary batch debarking.