DISTRIBUTION & SEPARATION

Star Feeder

Perfectly controlled material flow

Acrowood Star Feeder

The Star Feeder effectively meters the flow of materials to your screens and downstream processing equipment. The variable speed drive controller allows the Star Feeder to discharge at any desired rate. The hopper can be custom-designed to best suit the application type.

Star Feeder Features

-

Uniform distribution of material

-

Low maintenance

-

Heavy-duty construction

-

Uniform distribution

-

Efficient surge suppression

-

Option for either shaft mounted or foot mounted gear reducers.

Typical Applications

- Chip Plants

- OSB Plants

- Pellet Plants

- Pulp Mills

- Sawmills

- Shavings Mills

A newly constructed Star Feeder unit, staged in the Acrowood engineering shop, ready for shipping and deployment on-site at the pulp mill.

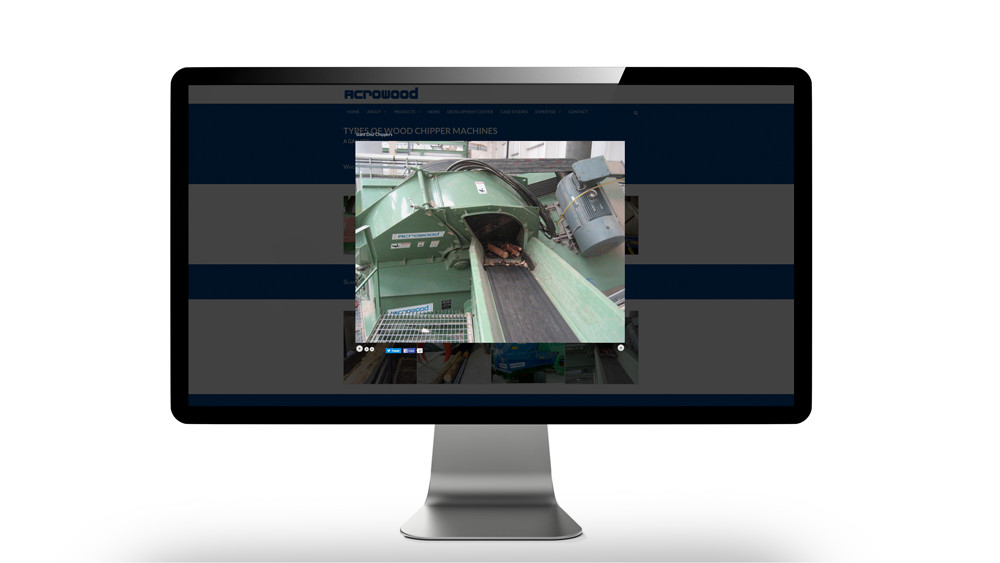

View from inside the top loading area of the Star Feeder where application materials accumulate and are steadily dispersed at the correct intervals for the downstream equipment processing, e.g. chip thickness screens.

The Star Feeder installed at this chip plant is mounted outside over-top of an Acrowood DiamondRoll Chip Thickness Screen. From this perspective the scale and magnitude of the Star Feeder can be appreciated.

The Star Feeder brochure

Request the star feeder machine brochure provided to you in PDF format for easy reading and printing.

Case Study: Pulping System Sensitivity to Chip Quality

Star feeders are used at various stages in the pulping process to regulate the distribution and flow of wood chips to downstream equipment such as a chip cracker for reprocessing.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.