Whole Log Chipper

Consistently high quality wood chips

Meet the Whole Log Chipper

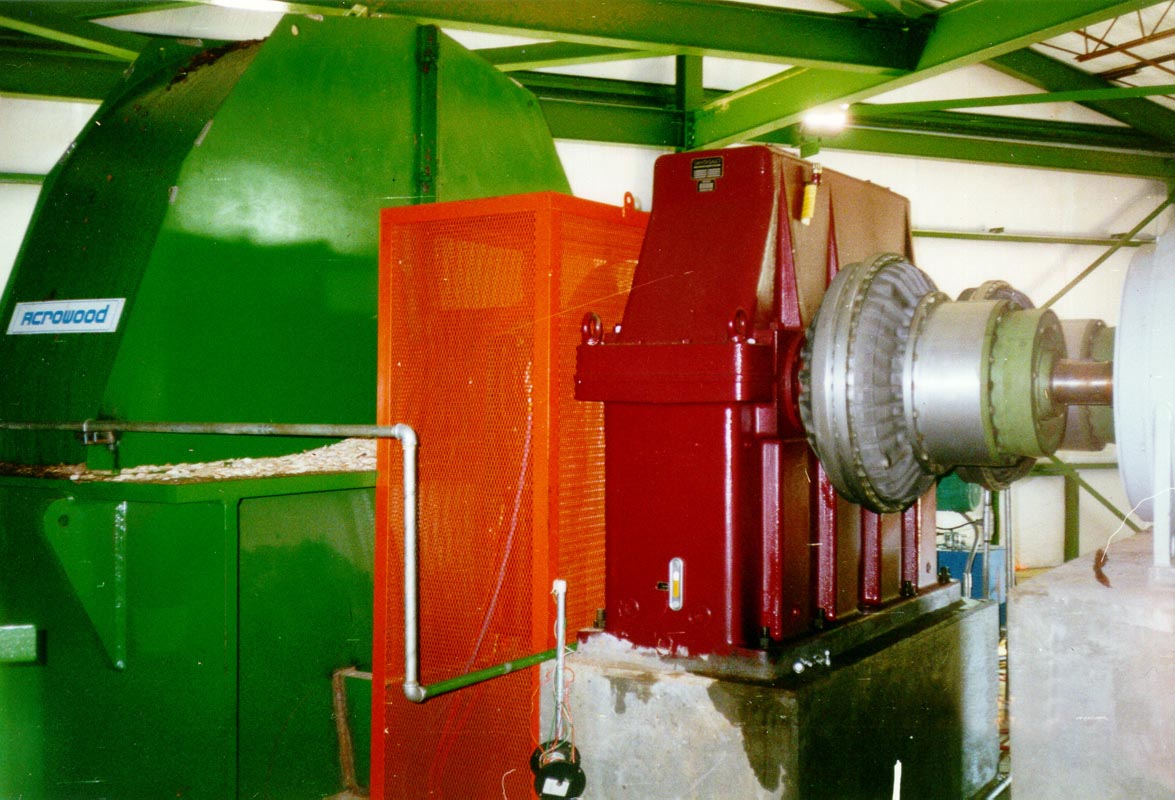

The heavy-duty design of the Whole Log Chippers produce high quality, uniform chips. Acrowood’s research into how chip length, chipper geometry, speed, species, and spout opening combine to affect chip quality has resulted in chippers that produce 90% acceptable chips with few pins, fines, or overthick chips.

Whole Log Chipper Features

- Produce more than 90% acceptable chips

- Minimize pins and overthick chips

- Increase ratio of large to small accept chips

- Feed spout arrangement stabilizes logs

- Chipper geometry optimized through research

- Anvils fully adjustable through side access spout door

- High quality chips are the result of optimized spout angles

- Uniform chips produced with radial knives

- Robust construction for 24/7 chip production for the pulp mill

- Horizontal or gravity feed configurations available

- Bottom or overhead discharge options

- Choice of drives

- Synchronous motor

- Optional gearbox configuration with one or more motors

The above video demonstrates the Acrowood Chipper in production at a mill, the logs are being fed to the Chipper via a conveyor system.

View more Acrowood forest product processing equipment videos on our channel.

Whole Log Chipper

The Acrowood newly configured Whole Log Chipper produces better chip quality are built to last and easy to maintain.

Acrowood’s research into how chip length, chipper geometry, speed, species and sprout opening combine to affect chip quality has resulted in chippers that product more than 90% acceptable chips, with few pins and overthick chips, and increased ratio of large to small accept chips.

A hinged access door provides excellent access to the chipper anvils.

More Features

- Produces over 90% acceptable chips

- Minimizes pins and overthick chips

- Increased ratio of large to small accept chip

- Feed sprout arrangement stabilizes logs

- Chipper geometry optimized through research

- Anvils fully adjustable through side access sprout door

Whole Log Chippers are made of high-grade steel fabricated with precision machinery in the USA.

Whole Log Chipper Design

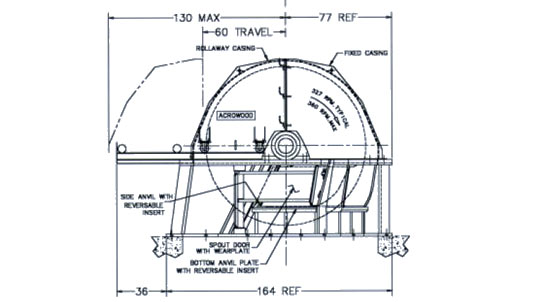

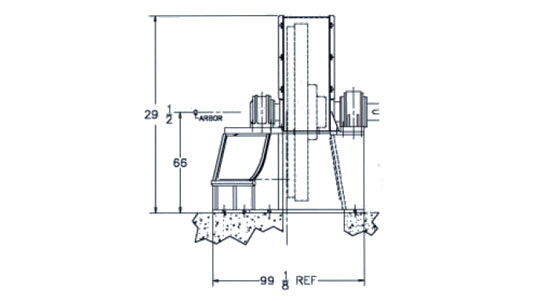

Changes in spout angle, knife edge angle, lambda angle, counter knife orientation and chipper speed have been optimized for whole log chipping.

Contributing to this outstanding chip quality is the new feed spout arrangement, configured to stabilize and direct logs. The “under the shaft” spout orientation has been combined with the proper angles of the spout, knife and anvil.

Stainless steel slot and endliners are available

Chipper Built To Last

- Reduce cost and maintenance time

- Optional stainless steel slot and end liners

- You may never need to rebuild your disc again or buy a spare

- Simple and easy knife to anvil clearance adjustments

The Acrowood Whole Log Chipper has features that will reduce your costs and time required for maintenance. With the optional stainless steel slot and end liners, which resist corrosion and wear, you can avoid the costly downtime and expense associated with rebuilding your chipper discs. You may never bear the expense of having to buy a spare disc.

Engineered to Last

We see Acrowood Whole Log Chippers still in service after more than 30 years of operation.

Need to adjust the knife to anvil clearance, so very critical to the production of perfect chips? It’s a simple task with this chipper. The bottom and side anvils are fully adjustable and easily accessed through the swing-open chipper spout door.

The new design maintains the features proven on more than 400 chippers manufactured over the past 100 years. At Acrowood, the right geometry, the right research, and the right manufacturer combine to make a perfect chipper for perfect chips.

Specifications: Whole Log Chipper

Disc Diameter

Spout Diameter + Gravity Feed

Spout Diameter + Horizontal Feed

Maximum RPM

Approximate Weight (lb.)*

WK² (Lb.Ft²)*

78``

NA

20``

538

29000

61000

90``

26``

NA

450

40000

100000

98``

NA

26``

428

49000

160000

116``

32``

30``

360

800000

344000

Knife Count: 4 to 15 knife designs available, depending on the chipper size and application.

Horsepower determined on a per application basis.

*Reflects values for standard bottom discharge chipper.

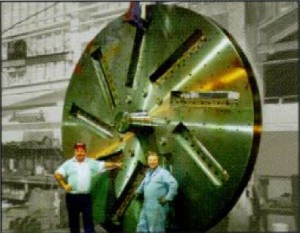

Acrowood 116″ Horizontal Feed Whole Log Chipper

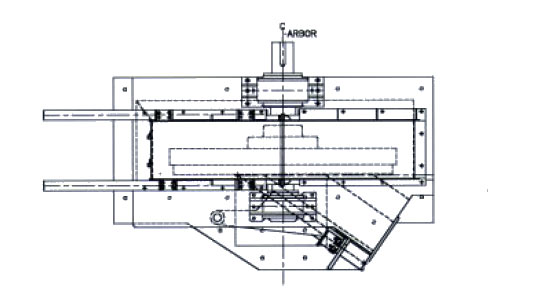

Whole Log Chipper (Top View)

Whole Log Chipper (Front View)

Whole Log Chipper (Side View)

The Whole Log Chipper brochure

Request the whole log chipper machine brochure in PDF format for easy reading and printing.

Case Study: Chip Thickness Screening and Chip Quality in the Pulp Mill

Modern whole log chipper designs have the capability of achieving accept chips in excess of 90%, with few fines, thins, and overs produced.

Case Study: Pulping System Sensitivity to Chip Quality

Whole log chippers are the second machine in the pulping process after debarking, the clean logs are rapidly feed into a chipper and cut to specific sizes and length for the pulping application.

Case Study: Chipper Upgrades and Replacements

Acrowood has been fortunate to have been involved in the redesign and upgrade of several chippers, both domestically and overseas. Some of these stories involve changes that have been relatively simple, and some have been fairly complex, involving replacement and redesign of fundamental components of the chipper.

View the Acrowood Corporate Video

Over a century of experience engineering equipment and machinery for pulp and paper, sawmill, panel board and biomass industries.

View Acrowood machinery installations at sawmills, pulp and paper mills, panel board mills and biomass facilities all around the world

View the gallery of chipping, cracking and slicing machines, chip screening & material distribution machines, and rotary & batch debarker machines.

The Whole Log Chipper is only one component in Acrowood’s complete line of chip processing equipment.

Request a download of our complete wood chip processing product line brochure